Page 649 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 649

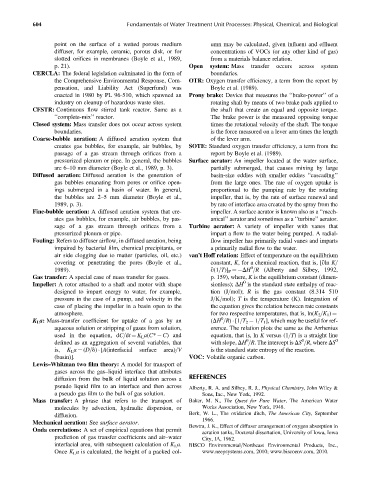

604 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

point on the surface of a wetted porous medium umn may be calculated, given influent and effluent

diffuser, for example, ceramic, porous disk, or for concentrations of VOCs (or any other kind of gas)

slotted orifices in membranes (Boyle et al., 1989, from a materials balance relation.

p. 21). Open system: Mass transfer occurs across system

CERCLA: The federal legislation culminated in the form of boundaries.

the Comprehensive Environmental Response, Com- OTR: Oxygen transfer efficiency, a term from the report by

pensation, and Liability Act (Superfund) was Boyle et al. (1989).

enacted in 1980 by PL 96-510, which spawned an Prony brake: Device that measures the ‘‘brake-power’’ of a

industry on cleanup of hazardous waste sites. rotating shaft by means of two brake pads applied to

CFSTR: Continuous flow stirred tank reactor. Same as a the shaft that create an equal and opposite torque.

‘‘complete-mix’’ reactor. The brake power is the measured opposing torque

Closed system: Mass transfer does not occur across system times the rotational velocity of the shaft. The torque

boundaries. is the force measured on a lever arm times the length

Coarse-bubble aeration: A diffused aeration system that of the lever arm.

creates gas bubbles, for example, air bubbles, by SOTE: Standard oxygen transfer efficiency, a term from the

passage of a gas stream through orifices from a report by Boyle et al. (1989).

pressurized plenum or pipe. In general, the bubbles Surface aerator: An impeller located at the water surface,

are 6–10 mm diameter (Boyle et al., 1989, p. 3). partially submerged, that causes mixing by large

Diffused aeration: Diffused aeration is the generation of basin-size eddies with smaller eddies ‘‘cascading’’

gas bubbles emanating from pores or orifice open- from the large ones. The rate of oxygen uptake is

ings submerged in a basin of water. In general, proportional to the pumping rate by the rotating

the bubbles are 2–5 mm diameter (Boyle et al., impeller, that is, by the rate of surface renewal and

1989, p. 3). by rate of interface area created by the spray from the

Fine-bubble aeration: A diffused aeration system that cre- impeller. A surface aerator is known also as a ‘‘mech-

ates gas bubbles, for example, air bubbles, by pas- anical’’ aerator and sometimes as a ‘‘turbine’’ aerator.

sage of a gas stream through orifices from a Turbine aerator: A variety of impeller with vanes that

pressurized plenum or pipe. impart a flow to the water being pumped. A radial-

Fouling: Refers to diffuser airflow, in diffused aeration, being flow impeller has primarily radial vanes and imparts

impaired by bacterial film, chemical precipitants, or a primarily radial flow to the water.

air side clogging due to matter (particles, oil, etc.) van’t Hoff relation: Effect of temperature on the equilibrium

covering or penetrating the pores (Boyle et al., constant, K, for a chemical reaction, that is, [qln K=

0

1989). q(1=T)] P ¼ DH =R (Alberty and Silbey, 1992,

Gas transfer: A special case of mass transfer for gases. p. 159), where, K is the equilibrium constant (dimen-

0

Impeller: A rotor attached to a shaft and motor with shape sionless); DH is the standard state enthalpy of reac-

designed to impart energy to water, for example, tion (J=mol); R is the gas constant (8.314 510

pressure in the case of a pump, and velocity in the J=K=mol); T is the temperature (K). Integration of

case of placing the impeller in a basin open to the the equation gives the relation between rate constants

atmosphere. for two respective temperatures, that is, ln(K 2 =K 1 ) ¼

0

K L a: Mass-transfer coefficient for uptake of a gas by an (DH =R) [1=T 2 1=T 1 ], which may be useful for ref-

aqueous solution or stripping of gases from solution, erence. The relation plots the same as the Arrhenius

used in the equation, dC=dt ¼ K L a(C* C) and equation, that is, ln K versus (1=T) is a straight line

0

0

defined as an aggregation of several variables, that with slope, DH =R. The intercept is DS =R, where DS 0

is, K L a ¼ (D=d) [A(interfacial surface area)=V is the standard state entropy of the reaction.

(basin)]. VOC: Volatile organic carbon.

Lewis–Whitman two film theory: A model for transport of

gases across the gas–liquid interface that attributes

diffusion from the bulk of liquid solution across a REFERENCES

pseudo liquid film to an interface and then across Alberty, R. A. and Silbey, R. J., Physical Chemistry, John Wiley &

a pseudo gas film to the bulk of gas solution. Sons, Inc., New York, 1992.

Mass transfer: A phrase that refers to the transport of Baker, M. N., The Quest for Pure Water, The American Water

molecules by advection, hydraulic dispersion, or Works Association, New York, 1948.

diffusion. Berk, W. L., The oxidation ditch, The American City, September

1966.

Mechanical aeration: See surface aerator.

Bewtra, J. K., Effect of diffuser arrangement of oxygen absorption in

Onda correlations: A set of empirical equations that permit

aeration tanks, Doctoral dissertation, University of Iowa, Iowa

prediction of gas transfer coefficients and air–water City, IA, 1962.

interfacial area, with subsequent calculation of K L a. BISCO Environmental=Northeast Environmental Products, Inc.,

Once K L a is calculated, the height of a packed col- www.neepsystems.com, 2010; www.biscoenv.com, 2010.