Page 216 - Gas Wettability of Reservoir Rock Surfaces with Porous Media

P. 216

200 Gas Wettability of Reservoir Rock Surfaces with Porous Media

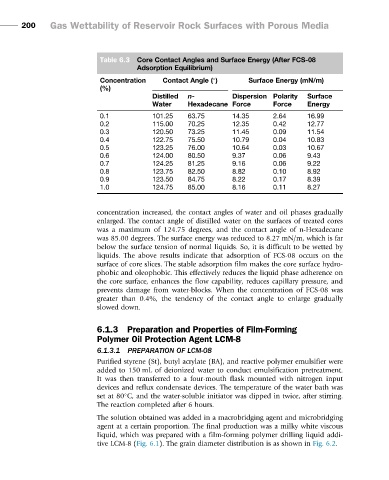

Table 6.3 Core Contact Angles and Surface Energy (After FCS-08

Adsorption Equilibrium)

Concentration Contact Angle ( ) Surface Energy (mN/m)

(%)

Distilled n- Dispersion Polarity Surface

Water Hexadecane Force Force Energy

0.1 101.25 63.75 14.35 2.64 16.99

0.2 115.00 70.25 12.35 0.42 12.77

0.3 120.50 73.25 11.45 0.09 11.54

0.4 122.75 75.50 10.79 0.04 10.83

0.5 123.25 76.00 10.64 0.03 10.67

0.6 124.00 80.50 9.37 0.06 9.43

0.7 124.25 81.25 9.16 0.06 9.22

0.8 123.75 82.50 8.82 0.10 8.92

0.9 123.50 84.75 8.22 0.17 8.39

1.0 124.75 85.00 8.16 0.11 8.27

concentration increased, the contact angles of water and oil phases gradually

enlarged. The contact angle of distilled water on the surfaces of treated cores

was a maximum of 124.75 degrees, and the contact angle of n-Hexadecane

was 85.00 degrees. The surface energy was reduced to 8.27 mN/m, which is far

below the surface tension of normal liquids. So, it is difficult to be wetted by

liquids. The above results indicate that adsorption of FCS-08 occurs on the

surface of core slices. The stable adsorption film makes the core surface hydro-

phobic and oleophobic. This effectively reduces the liquid phase adherence on

the core surface, enhances the flow capability, reduces capillary pressure, and

prevents damage from water-blocks. When the concentration of FCS-08 was

greater than 0.4%, the tendency of the contact angle to enlarge gradually

slowed down.

6.1.3 Preparation and Properties of Film-Forming

Polymer Oil Protection Agent LCM-8

6.1.3.1 PREPARATION OF LCM-08

Purified styrene (St), butyl acrylate (BA), and reactive polymer emulsifier were

added to 150 mL of deionized water to conduct emulsification pretreatment.

It was then transferred to a four-mouth flask mounted with nitrogen input

devices and reflux condensate devices. The temperature of the water bath was

set at 80 C, and the water-soluble initiator was dipped in twice, after stirring.

The reaction completed after 6 hours.

The solution obtained was added in a macrobridging agent and microbridging

agent at a certain proportion. The final production was a milky white viscous

liquid, which was prepared with a film-forming polymer drilling liquid addi-

tive LCM-8 (Fig. 6.1). The grain diameter distribution is as shown in Fig. 6.2.