Page 155 - Geothermal Energy Systems Exploration, Development, and Utilization

P. 155

3.4 Casing and Cementation 131

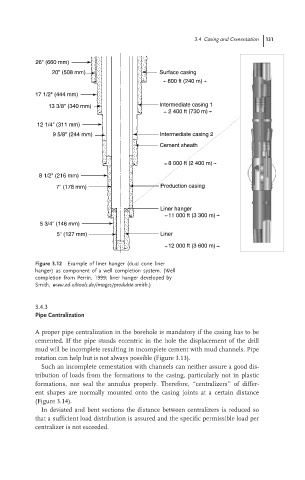

26" (660 mm)

20" (508 mm) Surface casing

800 ft (240 m)

17 1/2" (444 mm)

13 3/8" (340 mm) Intermediate casing 1

2 400 ft (730 m)

12 1/4" (311 mm)

9 5/8" (244 mm) Intermediate casing 2

Cement sheath

8 000 ft (2 400 m)

8 1/2" (216 mm)

7" (178 mm) Production casing

Liner hanger

11 000 ft (3 300 m)

5 3/4" (146 mm)

5" (127 mm) Liner

12 000 ft (3 600 m)

Figure 3.12 Example of liner hanger (dual cone liner

hanger) as component of a well completion system. (Well

completion from Perrin, 1999; liner hanger developed by

Smith, www.ed-oiltools.de/images/produkte-smith.)

3.4.3

Pipe Centralization

A proper pipe centralization in the borehole is mandatory if the casing has to be

cemented. If the pipe stands eccentric in the hole the displacement of the drill

mud will be incomplete resulting in incomplete cement with mud channels. Pipe

rotation can help but is not always possible (Figure 3.13).

Such an incomplete cementation with channels can neither assure a good dis-

tribution of loads from the formations to the casing, particularly not in plastic

formations, nor seal the annulus properly. Therefore, ‘‘centralizers’’ of differ-

ent shapes are normally mounted onto the casing joints at a certain distance

(Figure 3.14).

In deviated and bent sections the distance between centralizers is reduced so

that a sufficient load distribution is assured and the specific permissible load per

centralizer is not exceeded.