Page 156 - Geothermal Energy Systems Exploration, Development, and Utilization

P. 156

132 3 Drilling into Geothermal Reservoirs

No rotation Rotation

Flowing

cement

Gelled mud

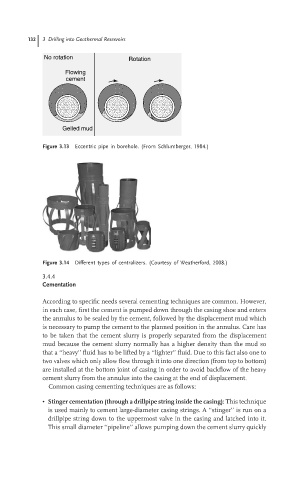

Figure 3.13 Eccentric pipe in borehole. (From Schlumberger, 1984.)

Figure 3.14 Different types of centralizers. (Courtesy of Weatherford, 2008.)

3.4.4

Cementation

According to specific needs several cementing techniques are common. However,

in each case, first the cement is pumped down through the casing shoe and enters

the annulus to be sealed by the cement, followed by the displacement mud which

is necessary to pump the cement to the planned position in the annulus. Care has

to be taken that the cement slurry is properly separated from the displacement

mud because the cement slurry normally has a higher density than the mud so

that a ‘‘heavy’’ fluid has to be lifted by a ‘‘lighter’’ fluid. Due to this fact also one to

two valves which only allow flow through it into one direction (from top to bottom)

are installed at the bottom joint of casing in order to avoid backflow of the heavy

cement slurry from the annulus into the casing at the end of displacement.

Common casing cementing techniques are as follows:

• Stinger cementation (through a drillpipe string inside the casing): This technique

is used mainly to cement large-diameter casing strings. A ‘‘stinger’’ is run on a

drillpipe string down to the uppermost valve in the casing and latched into it.

This small diameter ‘‘pipeline’’ allows pumping down the cement slurry quickly