Page 344 - Handbook of Thermal Analysis of Construction Materials

P. 344

Section 5.0 - Rice Husk Ash 321

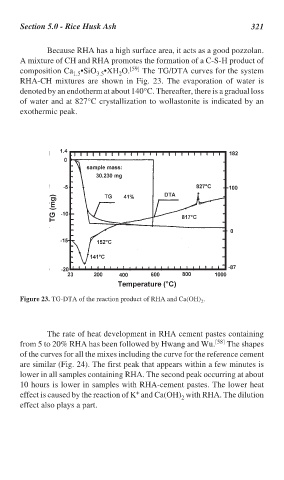

Because RHA has a high surface area, it acts as a good pozzolan.

A mixture of CH and RHA promotes the formation of a C-S-H product of

composition Ca •SiO •XH O. [59] The TG/DTA curves for the system

3.5

1.5

2

RHA-CH mixtures are shown in Fig. 23. The evaporation of water is

denoted by an endotherm at about 140°C. Thereafter, there is a gradual loss

of water and at 827°C crystallization to wollastonite is indicated by an

exothermic peak.

Figure 23. TG-DTA of the reaction product of RHA and Ca(OH) .

2

The rate of heat development in RHA cement pastes containing

from 5 to 20% RHA has been followed by Hwang and Wu. [58] The shapes

of the curves for all the mixes including the curve for the reference cement

are similar (Fig. 24). The first peak that appears within a few minutes is

lower in all samples containing RHA. The second peak occurring at about

10 hours is lower in samples with RHA-cement pastes. The lower heat

+

effect is caused by the reaction of K and Ca(OH) with RHA. The dilution

2

effect also plays a part.