Page 343 - Handbook of Thermal Analysis of Construction Materials

P. 343

320 Chapter 8 - Supplementary Cementing Materials

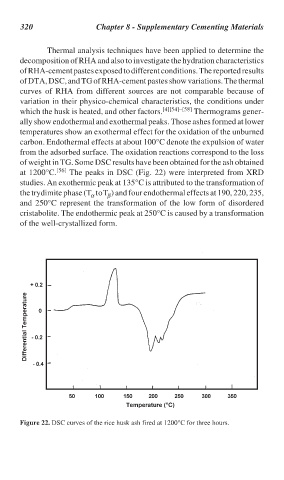

Thermal analysis techniques have been applied to determine the

decomposition of RHA and also to investigate the hydration characteristics

of RHA-cement pastes exposed to different conditions. The reported results

of DTA, DSC, and TG of RHA-cement pastes show variations. The thermal

curves of RHA from different sources are not comparable because of

variation in their physico-chemical characteristics, the conditions under

which the husk is heated, and other factors. [4][54]–[58] Thermograms gener-

ally show endothermal and exothermal peaks. Those ashes formed at lower

temperatures show an exothermal effect for the oxidation of the unburned

carbon. Endothermal effects at about 100°C denote the expulsion of water

from the adsorbed surface. The oxidation reactions correspond to the loss

of weight in TG. Some DSC results have been obtained for the ash obtained

at 1200°C. [56] The peaks in DSC (Fig. 22) were interpreted from XRD

studies. An exothermic peak at 135°C is attributed to the transformation of

the trydimite phase (T to T ) and four endothermal effects at 190, 220, 235,

α

β

and 250°C represent the transformation of the low form of disordered

cristabolite. The endothermic peak at 250°C is caused by a transformation

of the well-crystallized form.

Figure 22. DSC curves of the rice husk ash fired at 1200°C for three hours.