Page 338 - Handbook of Thermal Analysis of Construction Materials

P. 338

Section 4.0 - Slags 315

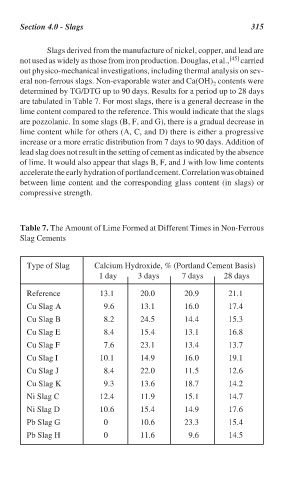

Slags derived from the manufacture of nickel, copper, and lead are

not used as widely as those from iron production. Douglas, et al., [45] carried

out physico-mechanical investigations, including thermal analysis on sev-

eral non-ferrous slags. Non-evaporable water and Ca(OH) contents were

2

determined by TG/DTG up to 90 days. Results for a period up to 28 days

are tabulated in Table 7. For most slags, there is a general decrease in the

lime content compared to the reference. This would indicate that the slags

are pozzolanic. In some slags (B, F, and G), there is a gradual decrease in

lime content while for others (A, C, and D) there is either a progressive

increase or a more erratic distribution from 7 days to 90 days. Addition of

lead slag does not result in the setting of cement as indicated by the absence

of lime. It would also appear that slags B, F, and J with low lime contents

accelerate the early hydration of portland cement. Correlation was obtained

between lime content and the corresponding glass content (in slags) or

compressive strength.

Table 7. The Amount of Lime Formed at Different Times in Non-Ferrous

Slag Cements

Type of Slag Calcium Hydroxide, % (Portland Cement Basis)

1 day 3 days 7 days 28 days

Reference 13.1 20.0 20.9 21.1

Cu Slag A 9.6 13.1 16.0 17.4

Cu Slag B 8.2 24.5 14.4 15.3

Cu Slag E 8.4 15.4 13.1 16.8

Cu Slag F 7.6 23.1 13.4 13.7

Cu Slag I 10.1 14.9 16.0 19.1

Cu Slag J 8.4 22.0 11.5 12.6

Cu Slag K 9.3 13.6 18.7 14.2

Ni Slag C 12.4 11.9 15.1 14.7

Ni Slag D 10.6 15.4 14.9 17.6

Pb Slag G 0 10.6 23.3 15.4

Pb Slag H 0 11.6 9.6 14.5