Page 628 - Handbook of Thermal Analysis of Construction Materials

P. 628

Section 3.0 - Applications 595

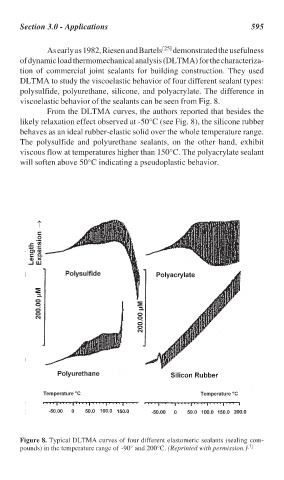

As early as 1982, Riesen and Bartels [25] demonstrated the usefulness

of dynamic load thermomechanical analysis (DLTMA) for the characteriza-

tion of commercial joint sealants for building construction. They used

DLTMA to study the viscoelastic behavior of four different sealant types:

polysulfide, polyurethane, silicone, and polyacrylate. The difference in

viscoelastic behavior of the sealants can be seen from Fig. 8.

From the DLTMA curves, the authors reported that besides the

likely relaxation effect observed at -50°C (see Fig. 8), the silicone rubber

behaves as an ideal rubber-elastic solid over the whole temperature range.

The polysulfide and polyurethane sealants, on the other hand, exhibit

viscous flow at temperatures higher than 150°C. The polyacrylate sealant

will soften above 50°C indicating a pseudoplastic behavior.

Figure 8. Typical DLTMA curves of four different elastomeric sealants (sealing com-

pounds) in the temperature range of -90° and 200°C. (Reprinted with permission.) [7]