Page 630 - Handbook of Thermal Analysis of Construction Materials

P. 630

Section 3.0 - Applications 597

exposed to xenon-arc radiation, heat and water spray for three weeks, heat

in a ventilated oven, and to acid dew and fog. Furthermore, artificial

weathering was combined with extension and compression. The properties

of the exposed and reference sealants were evaluated every 1000 hours by

using DSC.

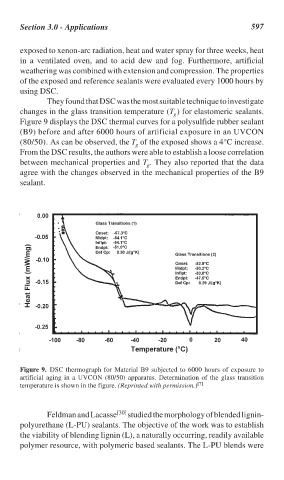

They found that DSC was the most suitable technique to investigate

changes in the glass transition temperature (T ) for elastomeric sealants.

g

Figure 9 displays the DSC thermal curves for a polysulfide rubber sealant

(B9) before and after 6000 hours of artificial exposure in an UVCON

(80/50). As can be observed, the T of the exposed shows a 4°C increase.

g

From the DSC results, the authors were able to establish a loose correlation

between mechanical properties and T . They also reported that the data

g

agree with the changes observed in the mechanical properties of the B9

sealant.

Figure 9. DSC thermograph for Material B9 subjected to 6000 hours of exposure to

artificial aging in a UVCON (80/50) apparatus. Determination of the glass transition

temperature is shown in the figure. (Reprinted with permission.) [7]

Feldman and Lacasse [30] studied the morphology of blended lignin-

polyurethane (L-PU) sealants. The objective of the work was to establish

the viability of blending lignin (L), a naturally occurring, readily available

polymer resource, with polymeric based sealants. The L-PU blends were