Page 631 - Handbook of Thermal Analysis of Construction Materials

P. 631

598 Chapter 14 - Sealants and Adhesives

exposed to accelerated and natural weathering. The control, pure L, and

exposed blends were analyzed by DSC. The control specimens were

subjected to 23°C and 50% RH. The accelerated weathering regimen

performed in a weathering chamber, consisted of 170 cycles, each between

temperatures of -30° and 40°C, four times every twenty-four hours with

twelve hours daily UV-radiation exposure. Samples were continuously

artificially weathered for 180 days. The L-PU specimens were exposed to

exterior weather conditions in central Montreal for thirty-seven weeks

between July 15, 1985 and March 31, 1986. During this period, temperature

varied between +32.6° and -26.7°C.

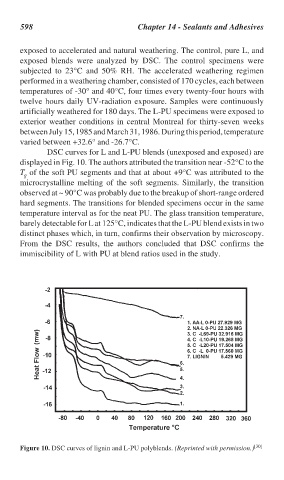

DSC curves for L and L-PU blends (unexposed and exposed) are

displayed in Fig. 10. The authors attributed the transition near -52°C to the

T of the soft PU segments and that at about +9°C was attributed to the

g

microcrystalline melting of the soft segments. Similarly, the transition

observed at ~ 90°C was probably due to the breakup of short-range ordered

hard segments. The transitions for blended specimens occur in the same

temperature interval as for the neat PU. The glass transition temperature,

barely detectable for L at 125°C, indicates that the L-PU blend exists in two

distinct phases which, in turn, confirms their observation by microscopy.

From the DSC results, the authors concluded that DSC confirms the

immiscibility of L with PU at blend ratios used in the study.

Figure 10. DSC curves of lignin and L-PU polyblends. (Reprinted with permission.) [30]