Page 48 - HVAC Pump Handbook

P. 48

Rishel_CH03.qxd 21/4/06 6:07 PM Page 45

Piping System Friction

Piping System Friction 45

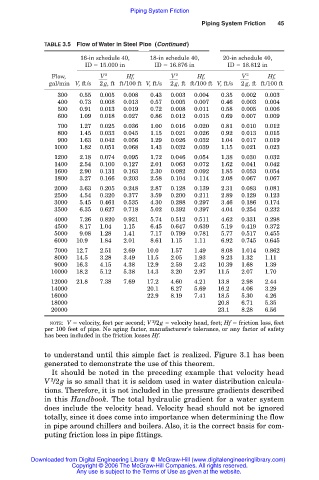

TABLE 3.5 Flow of Water in Steel Pipe (Continued )

16-in schedule 40, 18-in schedule 40, 20-in schedule 40,

ID 15.000 in ID 16.876 in ID 18.812 in

V

Flow, 2 Hf, 2 Hf, 2 Hf,

V

V

gal/min V, ft/s 2 g, ft ft/100 ft V, ft/s 2 g, ft ft/100 ft V, ft/s 2 g, ft ft/100 ft

00300 00.55 0.005 0.008 00.43 0.003 0.004 00.35 0.002 0.003

00400 00.73 0.008 0.013 00.57 0.005 0.007 00.46 0.003 0.004

00500 00.91 0.013 0.019 00.72 0.008 0.011 00.58 0.005 0.006

00600 01.09 0.018 0.027 00.86 0.012 0.015 00.69 0.007 0.009

00700 01.27 0.025 0.036 01.00 0.016 0.020 00.81 0.010 0.012

00800 01.45 0.033 0.045 01.15 0.021 0.026 00.92 0.013 0.015

00900 01.63 0.042 0.056 01.29 0.026 0.032 01.04 0.017 0.019

01000 01.82 0.051 0.068 01.43 0.032 0.039 01.15 0.021 0.023

01200 02.18 0.074 0.095 01.72 0.046 0.054 01.38 0.030 0.032

01400 02.54 0.100 0.127 02.01 0.063 0.072 01.62 0.041 0.042

01600 02.90 0.131 0.163 02.30 0.082 0.092 01.85 0.053 0.054

01800 03.27 0.166 0.203 02.58 0.104 0.114 02.08 0.067 0.067

02000 03.63 0.205 0.248 02.87 0.128 0.139 02.31 0.083 0.081

02500 04.54 0.320 0.377 03.59 0.200 0.211 02.89 0.129 0.123

03000 05.45 0.461 0.535 04.30 0.288 0.297 03.46 0.186 0.174

03500 06.35 0.627 0.718 05.02 0.392 0.397 04.04 0.254 0.232

04000 07.26 0.820 0.921 05.74 0.512 0.511 04.62 0.331 0.298

04500 08.17 1.04 1.15 06.45 0.647 0.639 05.19 0.419 0.372

05000 09.08 1.28 1.41 07.17 0.799 0.781 05.77 0.517 0.455

06000 10.9 1.84 2.01 08.61 1.15 1.11 06.92 0.745 0.645

07000 12.7 2.51 2.69 10.0 1.57 1.49 08.08 1.014 0.862

08000 14.5 3.28 3.49 11.5 2.05 1.93 09.23 1.32 1.11

09000 16.3 4.15 4.38 12.9 2.59 2.42 10.39 1.68 1.39

10000 18.2 5.12 5.38 14.3 3.20 2.97 11.5 2.07 1.70

12000 21.8 7.38 7.69 17.2 4.60 4.21 13.8 2.98 2.44

14000 20.1 6.27 5.69 16.2 4.06 3.29

16000 22.9 8.19 7.41 18.5 5.30 4.26

18000 20.8 6.71 5.35

20000 23.1 8.28 6.56

2

NOTE: V velocity, feet per second; V /2g velocity head, feet; Hf friction loss, feet

per 100 feet of pipe. No aging factor, manufacturer’s tolerance, or any factor of safety

has been included in the friction losses Hf.

to understand until this simple fact is realized. Figure 3.1 has been

generated to demonstrate the use of this theorem.

It should be noted in the preceding example that velocity head

V /2g is so small that it is seldom used in water distribution calcula-

2

tions. Therefore, it is not included in the pressure gradients described

in this Handbook. The total hydraulic gradient for a water system

does include the velocity head. Velocity head should not be ignored

totally, since it does come into importance when determining the flow

in pipe around chillers and boilers. Also, it is the correct basis for com-

puting friction loss in pipe fittings.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.