Page 47 - Handbook Of Multiphase Flow Assurance

P. 47

42 2. Initial diagnosis and solution of flow assurance production problems in operations

In absence of a proper laboratory CPM, a field-grade cross-polarized microscopy may be

performed using two polarizer camera filters or two pairs of polarized eyeglasses. A thin

sample of solid (such as wax) is placed between the two polarizers, and polarizers are turned

relative to each other until no visible light passes through the assembly. Some crystals such

as wax or ice can rotate the plane of light polarization, which can be observed in CPM as

light passing through the crossed polarizers. A light shining through the sample in a CPM

helps tell whether this flow assurance sample is one of the deposits which can rotate light

polarization.

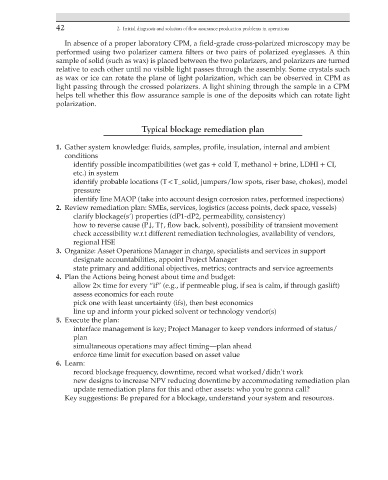

Typical blockage remediation plan

1. Gather system knowledge: fluids, samples, profile, insulation, internal and ambient

conditions

identify possible incompatibilities (wet gas + cold T, methanol + brine, LDHI + CI,

etc.) in system

identify probable locations (T < T_solid, jumpers/low spots, riser base, chokes), model

pressure

identify line MAOP (take into account design corrosion rates, performed inspections)

2. Review remediation plan: SMEs, services, logistics (access points, deck space, vessels)

clarify blockage(s′) properties (dP1-dP2, permeability, consistency)

how to reverse cause (P↓, T↑, flow back, solvent), possibility of transient movement

check accessibility w.r.t different remediation technologies, availability of vendors,

regional HSE

3. Organize: Asset Operations Manager in charge, specialists and services in support

designate accountabilities, appoint Project Manager

state primary and additional objectives, metrics; contracts and service agreements

4. Plan the Actions being honest about time and budget:

allow 2× time for every “if” (e.g., if permeable plug, if sea is calm, if through gaslift)

assess economics for each route

pick one with least uncertainty (ifs), then best economics

line up and inform your picked solvent or technology vendor(s)

5. Execute the plan:

interface management is key; Project Manager to keep vendors informed of status/

plan

simultaneous operations may affect timing—plan ahead

enforce time limit for execution based on asset value

6. Learn:

record blockage frequency, downtime, record what worked/didn't work

new designs to increase NPV reducing downtime by accommodating remediation plan

update remediation plans for this and other assets: who you're gonna call?

Key suggestions: Be prepared for a blockage, understand your system and resources.