Page 134 - Handbook of Thermal Analysis of Construction Materials

P. 134

Section 7.0 - Portland Cement 117

cement made at different water:cement ratios indicates that the first intense

inflection occurs much earlier in the supersulfated cement. [63] The high

strength of supersulfated cement is due to the dense structure of ettringite

produced at early times of hydration.

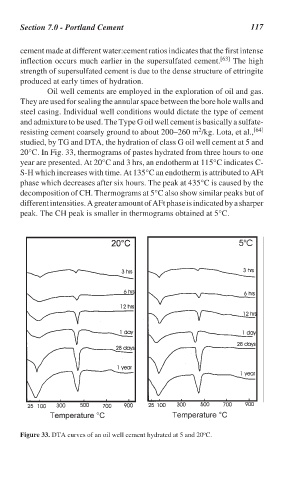

Oil well cements are employed in the exploration of oil and gas.

They are used for sealing the annular space between the bore hole walls and

steel casing. Individual well conditions would dictate the type of cement

and admixture to be used. The Type G oil well cement is basically a sulfate-

2

resisting cement coarsely ground to about 200–260 m /kg. Lota, et al., [64]

studied, by TG and DTA, the hydration of class G oil well cement at 5 and

20°C. In Fig. 33, thermograms of pastes hydrated from three hours to one

year are presented. At 20°C and 3 hrs, an endotherm at 115°C indicates C-

S-H which increases with time. At 135°C an endotherm is attributed to AFt

phase which decreases after six hours. The peak at 435°C is caused by the

decomposition of CH. Thermograms at 5°C also show similar peaks but of

different intensities. A greater amount of AFt phase is indicated by a sharper

peak. The CH peak is smaller in thermograms obtained at 5°C.

o

Figure 33. DTA curves of an oil well cement hydrated at 5 and 20 C.