Page 109 - Handbook of Adhesion Promoters

P. 109

102 Properties of Adhesion Promoters

7.1 ACRYLATES

USE

Manufacturer: Allnex, Dymax Corporation, Sartomer/Arkema Group

Outstanding properties: Excellent optical clarity, resilience, tenacious adhesion and non-yellow-

ing effect, chemical, and thermal resistance, offers hydrolytic stability, low shrinkage, toughness,

high tensile strength, and enhances weatherability

Recommended for resins: ABS, PC, PMMA Typical dose: 3-7 wt%

Recommended for products: coatings, nail coating, 3D printing inks, wood & floor coating, elec-

tronic coatings and inks

Recommended applications: adhesion promoter, reactive tackifier, industrial coatings

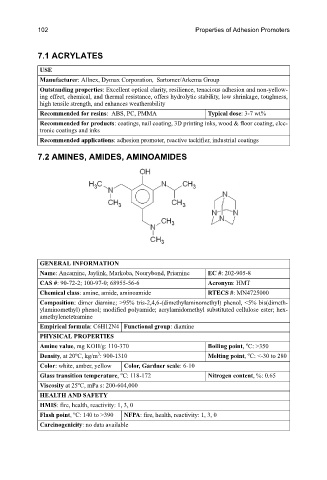

7.2 AMINES, AMIDES, AMINOAMIDES

GENERAL INFORMATION

Name: Ancamine, Jaylink, Markoba, Nourybond, Priamine EC #: 202-905-8

CAS #: 90-72-2; 100-97-0; 68955-56-6 Acronym: HMT

Chemical class: amine, amide, aminoamide RTECS #: MN4725000

Composition: dimer diamine; >95% tris-2,4,6-(dimethylaminomethyl) phenol, <5% bis(dimeth-

ylaminomethyl) phenol; modified polyamide; acrylamidomethyl substituted cellulose ester; hex-

amethylenetetramine

Empirical formula: C6H12N4 Functional group: diamine

PHYSICAL PROPERTIES

o

Amine value, mg KOH/g: 110-370 Boiling point, C: >350

o

3

o

Density, at 20 C, kg/m : 900-1310 Melting point, C: <-30 to 280

Color: white, amber, yellow Color, Gardner scale: 6-10

o

Glass transition temperature, C: 118-172 Nitrogen content, %: 0.65

o

Viscosity at 25 C, mPa s: 200-604,000

HEALTH AND SAFETY

HMIS: fire, health, reactivity: 1, 3, 0

o

Flash point, C: 140 to >390 NFPA: fire, health, reactivity: 1, 3, 0

Carcinogenicity: no data available