Page 150 - Handbook of Adhesives and Sealants

P. 150

Joint Design 119

designate a depth relationship that holds for all sealant widths. The

following rules cover joint designs and sealants commonly used in con-

struction applications. 14

1

1

1. The minimum size joint should be ⁄4 ⁄4 in.

1

1

2. For widths from ⁄4 to ⁄2 in., depth should equal the width.

1

1

3. For widths from ⁄2 to 1 in., depth should be approximately ⁄2 in.

5

1

4. For widths more than 1 in., depths may be ⁄2 to ⁄8 in., depending

on the width and application area, as well as the type of sealant.

The minimum joint size is given because it is difficult to seal a joint

that is any smaller unless a liquid sealant is used. A depth of at least

1

⁄4 in. is needed to ensure adhesion to the side of the joint.

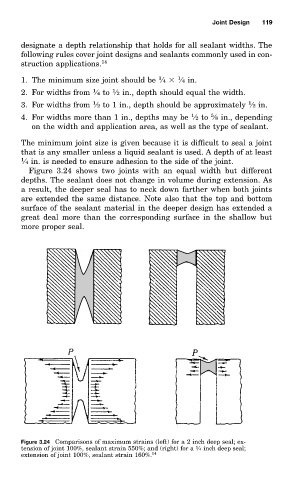

Figure 3.24 shows two joints with an equal width but different

depths. The sealant does not change in volume during extension. As

a result, the deeper seal has to neck down farther when both joints

are extended the same distance. Note also that the top and bottom

surface of the sealant material in the deeper design has extended a

great deal more than the corresponding surface in the shallow but

more proper seal.

Figure 3.24 Comparisons of maximum strains (left) for a 2 inch deep seal; ex-

tension of joint 100%, sealant strain 550%; and (right) for a ⁄4 inch deep seal;

1

extension of joint 100%, sealant strain 160%. 14