Page 153 - Handbook of Adhesives and Sealants

P. 153

122 Chapter Three

1

1

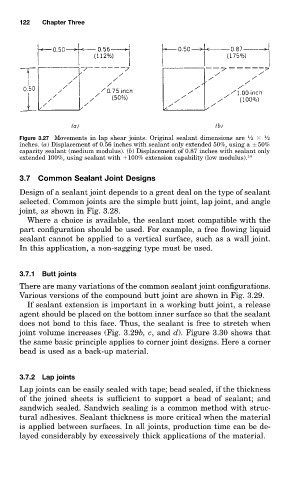

Figure 3.27 Movements in lap shear joints. Original sealant dimensions are ⁄2 ⁄2

inches. (a) Displacement of 0.56 inches with sealant only extended 50%, using a 50%

capacity sealant (medium modulus). (b) Displacement of 0.87 inches with sealant only

extended 100%, using sealant with 100% extension capability (low modulus). 14

3.7 Common Sealant Joint Designs

Design of a sealant joint depends to a great deal on the type of sealant

selected. Common joints are the simple butt joint, lap joint, and angle

joint, as shown in Fig. 3.28.

Where a choice is available, the sealant most compatible with the

part configuration should be used. For example, a free flowing liquid

sealant cannot be applied to a vertical surface, such as a wall joint.

In this application, a non-sagging type must be used.

3.7.1 Butt joints

There are many variations of the common sealant joint configurations.

Various versions of the compound butt joint are shown in Fig. 3.29.

If sealant extension is important in a working butt joint, a release

agent should be placed on the bottom inner surface so that the sealant

does not bond to this face. Thus, the sealant is free to stretch when

joint volume increases (Fig. 3.29b, c, and d). Figure 3.30 shows that

the same basic principle applies to corner joint designs. Here a corner

bead is used as a back-up material.

3.7.2 Lap joints

Lap joints can be easily sealed with tape; bead sealed, if the thickness

of the joined sheets is sufficient to support a bead of sealant; and

sandwich sealed. Sandwich sealing is a common method with struc-

tural adhesives. Sealant thickness is more critical when the material

is applied between surfaces. In all joints, production time can be de-

layed considerably by excessively thick applications of the material.