Page 154 - Handbook of Adhesives and Sealants

P. 154

Joint Design 123

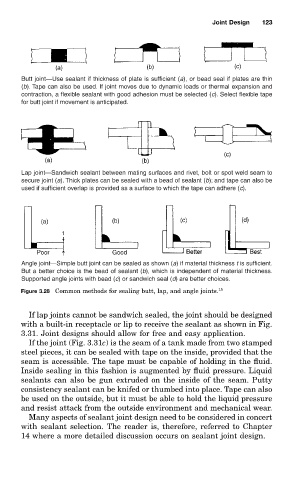

Butt joint—Use sealant if thickness of plate is sufficient (a), or bead seal if plates are thin

(b). Tape can also be used. If joint moves due to dynamic loads or thermal expansion and

contraction, a flexible sealant with good adhesion must be selected (c). Select flexible tape

for butt joint if movement is anticipated.

Lap joint—Sandwich sealant between mating surfaces and rivet, bolt or spot weld seam to

secure joint (a). Thick plates can be sealed with a bead of sealant (b); and tape can also be

used if sufficient overlap is provided as a surface to which the tape can adhere (c).

Angle joint—Simple butt joint can be sealed as shown (a) if material thickness t is sufficient.

But a better choice is the bead of sealant (b), which is independent of material thickness.

Supported angle joints with bead (c) or sandwich seal (d) are better choices.

Figure 3.28 Common methods for sealing butt, lap, and angle joints. 15

If lap joints cannot be sandwich sealed, the joint should be designed

with a built-in receptacle or lip to receive the sealant as shown in Fig.

3.31. Joint designs should allow for free and easy application.

If the joint (Fig. 3.31c) is the seam of a tank made from two stamped

steel pieces, it can be sealed with tape on the inside, provided that the

seam is accessible. The tape must be capable of holding in the fluid.

Inside sealing in this fashion is augmented by fluid pressure. Liquid

sealants can also be gun extruded on the inside of the seam. Putty

consistency sealant can be knifed or thumbed into place. Tape can also

be used on the outside, but it must be able to hold the liquid pressure

and resist attack from the outside environment and mechanical wear.

Many aspects of sealant joint design need to be considered in concert

with sealant selection. The reader is, therefore, referred to Chapter

14 where a more detailed discussion occurs on sealant joint design.