Page 218 - Handbook of Adhesives and Sealants

P. 218

Quality Control and Nondestructive Tests 189

area. Shear waves can also be introduced into the structure with a

5

wedge shaped transducer. This technique is effective in analyzing

sandwich structures.

Bonded structures that are ultrasonically tested by the immersion

method often use a C-scan recorder to record the test. This recorder

is an electrical device that accepts signals from the pulser/receiver

and prints out a plan view of the part. The ultrasonic search unit is

automatically scanned over the part. The ultrasonic signals for bond

or unbond are detected from built-in reference standards. C-scan NDT

techniques are used extensively by aircraft manufacturers to inspect

bonded parts.

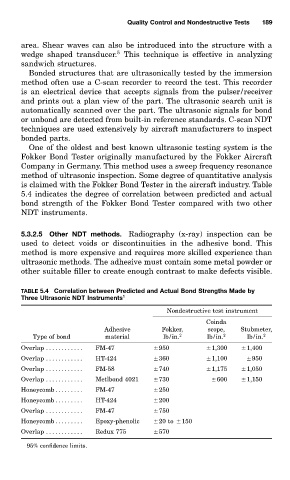

One of the oldest and best known ultrasonic testing system is the

Fokker Bond Tester originally manufactured by the Fokker Aircraft

Company in Germany. This method uses a sweep frequency resonance

method of ultrasonic inspection. Some degree of quantitative analysis

is claimed with the Fokker Bond Tester in the aircraft industry. Table

5.4 indicates the degree of correlation between predicted and actual

bond strength of the Fokker Bond Tester compared with two other

NDT instruments.

5.3.2.5 Other NDT methods. Radiography (x-ray) inspection can be

used to detect voids or discontinuities in the adhesive bond. This

method is more expensive and requires more skilled experience than

ultrasonic methods. The adhesive must contain some metal powder or

other suitable filler to create enough contrast to make defects visible.

TABLE 5.4 Correlation between Predicted and Actual Bond Strengths Made by

Three Ultrasonic NDT Instruments 1

Nondestructive test instrument

Coinda

Adhesive Fokker, scope, Stubmeter,

Type of bond material lb/in. 2 lb/in. 2 lb/in. 2

Overlap ............ FM-47 950 1,300 1,400

Overlap ............ HT-424 360 1,100 950

Overlap ............ FM-58 740 1,175 1,050

Overlap ............ Metlbond 4021 730 600 1,150

Honeycomb ......... FM-47 250

Honeycomb ......... HT-424 200

Overlap ............ FM-47 750

Honeycomb ......... Epoxy-phenolic 20 to 150

Overlap ............ Redux 775 570

95% confidence limits.