Page 284 - Handbook of Adhesives and Sealants

P. 284

Surfaces and Surface Preparation 249

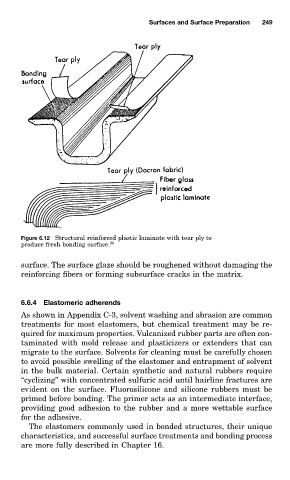

Figure 6.12 Structural reinforced plastic laminate with tear ply to

produce fresh bonding surface. 20

surface. The surface glaze should be roughened without damaging the

reinforcing fibers or forming subsurface cracks in the matrix.

6.6.4 Elastomeric adherends

As shown in Appendix C-3, solvent washing and abrasion are common

treatments for most elastomers, but chemical treatment may be re-

quired for maximum properties. Vulcanized rubber parts are often con-

taminated with mold release and plasticizers or extenders that can

migrate to the surface. Solvents for cleaning must be carefully chosen

to avoid possible swelling of the elastomer and entrapment of solvent

in the bulk material. Certain synthetic and natural rubbers require

‘‘cyclizing’’ with concentrated sulfuric acid until hairline fractures are

evident on the surface. Fluorosilicone and silicone rubbers must be

primed before bonding. The primer acts as an intermediate interface,

providing good adhesion to the rubber and a more wettable surface

for the adhesive.

The elastomers commonly used in bonded structures, their unique

characteristics, and successful surface treatments and bonding process

are more fully described in Chapter 16.