Page 337 - Handbook of Adhesives and Sealants

P. 337

Adhesive Classifications 295

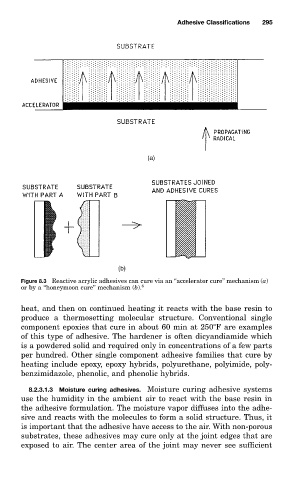

Figure 8.3 Reactive acrylic adhesives can cure via an ‘‘accelerator cure’’ mechanism (a)

or by a ‘‘honeymoon cure’’ mechanism (b). 6

heat, and then on continued heating it reacts with the base resin to

produce a thermosetting molecular structure. Conventional single

component epoxies that cure in about 60 min at 250 F are examples

of this type of adhesive. The hardener is often dicyandiamide which

is a powdered solid and required only in concentrations of a few parts

per hundred. Other single component adhesive families that cure by

heating include epoxy, epoxy hybrids, polyurethane, polyimide, poly-

benzimidazole, phenolic, and phenolic hybrids.

8.2.3.1.3 Moisture curing adhesives. Moisture curing adhesive systems

use the humidity in the ambient air to react with the base resin in

the adhesive formulation. The moisture vapor diffuses into the adhe-

sive and reacts with the molecules to form a solid structure. Thus, it

is important that the adhesive have access to the air. With non-porous

substrates, these adhesives may cure only at the joint edges that are

exposed to air. The center area of the joint may never see sufficient