Page 340 - Handbook of Adhesives and Sealants

P. 340

298 Chapter Eight

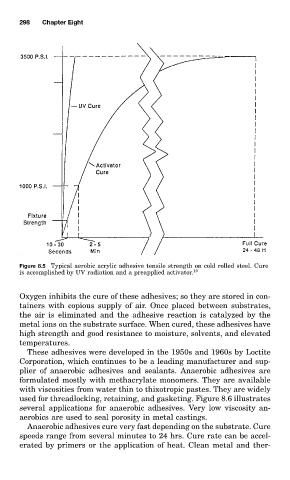

Figure 8.5 Typical aerobic acrylic adhesive tensile strength on cold rolled steel. Cure

is accomplished by UV radiation and a preapplied activator. 10

Oxygen inhibits the cure of these adhesives; so they are stored in con-

tainers with copious supply of air. Once placed between substrates,

the air is eliminated and the adhesive reaction is catalyzed by the

metal ions on the substrate surface. When cured, these adhesives have

high strength and good resistance to moisture, solvents, and elevated

temperatures.

These adhesives were developed in the 1950s and 1960s by Loctite

Corporation, which continues to be a leading manufacturer and sup-

plier of anaerobic adhesives and sealants. Anaerobic adhesives are

formulated mostly with methacrylate monomers. They are available

with viscosities from water thin to thixotropic pastes. They are widely

used for threadlocking, retaining, and gasketing. Figure 8.6 illustrates

several applications for anaerobic adhesives. Very low viscosity an-

aerobics are used to seal porosity in metal castings.

Anaerobic adhesives cure very fast depending on the substrate. Cure

speeds range from several minutes to 24 hrs. Cure rate can be accel-

erated by primers or the application of heat. Clean metal and ther-