Page 538 - Handbook of Adhesives and Sealants

P. 538

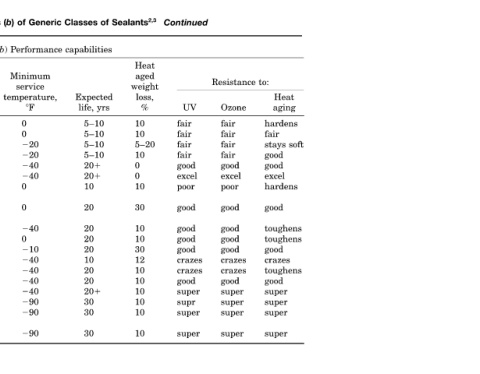

Heat aging hardens fair stays soft good good excel hardens good toughens toughens good crazes toughens good super super super super

Resistance to: Ozone fair fair fair fair good excel poor good good good good crazes crazes good super super super super

Continued UV fair fair fair fair good excel poor good good good good crazes crazes good super supr super super

Application Characteristics (a) and Performance Capabilities (b) of Generic Classes of Sealants 2,3

Heat aged weight loss, % 10 10 5–20 10 0 0 10 30 10 10 30 12 10 10 10 10 10 10

(b) Performance capabilities Minimum service Expected temperature, life, yrs F 5–10 0 5–10 0 5–10 20 5–10 20 20 40 20 40 10 0 20 0 20 40 20 0 2

Maximum service temperature, F 150 150 200 200 180 180 180 180 200 180 180 250 250 250 250 400 400 400

Recovery poor poor poor poor none none fair good fair fair good fair good excellent excellent excellent excellent excelent

Movement, / % 7.5–10 12.5–25 25 and 50 100 to 50

2 5 5–10 10 10 10 25 12.5 12.5 25 25 50 50 50

Generic type Butyl/polybutylene One part polysulfide Two part polysulfide One part urethane Two part urethane Silicone structural (medium modulus) Silicone (low modu

TABLE 12.5 Oil base Oil resin base Butyl mastics Butyl curable Polyisobutylene Emulsion acrylic (high modulus) Emulsion acrylic (low modulus) Hypalon Solvent acrylic B