Page 201 - Handbook of Electrical Engineering

P. 201

CABLES, WIRES AND CABLE INSTALLATION PRACTICES 185

Tin is also used as a coating for copper armour wires or armour braiding where rubber

compounds are used in the inner or outer sheathing.

9.1.3 Phosphor Bronze

Phosphor bronze is an alloy of mainly copper, 5 to 10% tin and approximately 0.1% phosphorous.

The alloy has superior mechanical strength when compared with copper. It is also very resistant to

corrosion, particularly in the presence of water.

Phosphor bronze is used as wire in the armouring of cables to provide moderate protection

against mechanical damage. It is formed into a tightly woven braid to form a non-magnetic, highly

conductive, armoring and electromagnetic screen.

It is a practical alternative to tinned copper braid in many applications where steel wire should

not be used.

The alloy is also used in the form of a thin tape for the purpose of repelling insects e.g.,

ants, termites and marine teredo worms. The tapes are placed underneath the main armouring and

on top of the inner sheathing. Table 9.2 shows some of the electrical and physical properties of

phosphor bronze.

9.1.4 Galvanised Steel

Galvanised steel is used for the cable armour where a high degree of mechanical protection is required,

and where high pulling forces are experienced during the installation of the cable, especially in the

laying of submarine cables. The armour wires are formed into a helical cage to give the highest

protection or as a braid when flexibility is required during the installation and a lesser level of

protection can be accepted.

Mild steel is used for the armouring of cables laid on land. For submarine cables the material

can be specified as carbon steel, which has a higher tensile strength.

The depth of the galvanising is specified in the international standards. The cross-sectional

area of each armour wire (in a helix and not in a braid) varies from typically 0.9 mm for small

2

2

power and control cables e.g. 1.5 and 2.5 mm conductors, to 2.5 mm for 400 mm low voltage high

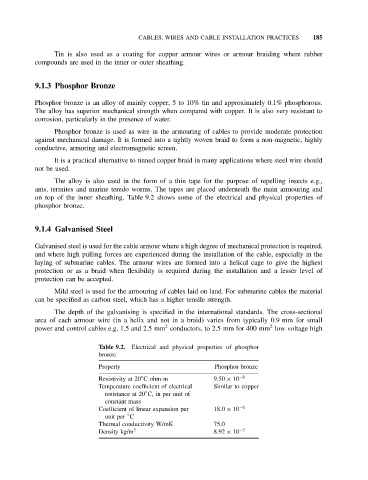

Table 9.2. Electrical and physical properties of phosphor

bronze

Property Phosphor bronze

◦

Resistivity at 20 C ohm-m 9.50 × 10 −8

Temperature coefficient of electrical Similar to copper

◦

resistance at 20 C, in per unit of

constant mass

Coefficient of linear expansion per 18.0 × 10 −6

◦

unit per C

Thermal conductivity W/mK 75.0

Density kg/m 3 8.92 × 10 −3