Page 174 - Handbook of Energy Engineering Calculations

P. 174

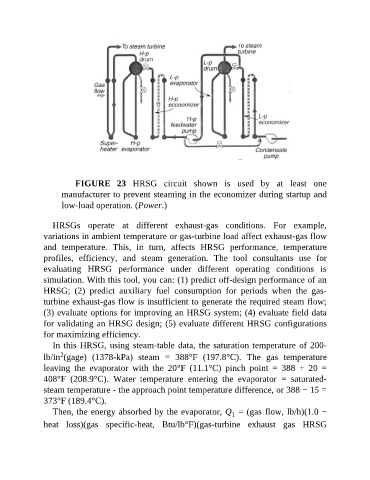

FIGURE 23 HRSG circuit shown is used by at least one

manufacturer to prevent steaming in the economizer during startup and

low-load operation. (Power.)

HRSGs operate at different exhaust-gas conditions. For example,

variations in ambient temperature or gas-turbine load affect exhaust-gas flow

and temperature. This, in turn, affects HRSG performance, temperature

profiles, efficiency, and steam generation. The tool consultants use for

evaluating HRSG performance under different operating conditions is

simulation. With this tool, you can: (1) predict off-design performance of an

HRSG; (2) predict auxiliary fuel consumption for periods when the gas-

turbine exhaust-gas flow is insufficient to generate the required steam flow;

(3) evaluate options for improving an HRSG system; (4) evaluate field data

for validating an HRSG design; (5) evaluate different HRSG configurations

for maximizing efficiency.

In this HRSG, using steam-table data, the saturation temperature of 200-

2

lb/in (gage) (1378-kPa) steam = 388°F (197.8°C). The gas temperature

leaving the evaporator with the 20°F (11.1°C) pinch point = 388 + 20 =

408°F (208.9°C). Water temperature entering the evaporator = saturated-

steam temperature - the approach point temperature difference, or 388 − 15 =

373°F (189.4°C).

Then, the energy absorbed by the evaporator, Q = (gas flow, lb/h)(1.0 −

1

heat loss)(gas specific-heat, Btu/lb°F)(gas-turbine exhaust gas HRSG