Page 179 - Handbook of Energy Engineering Calculations

P. 179

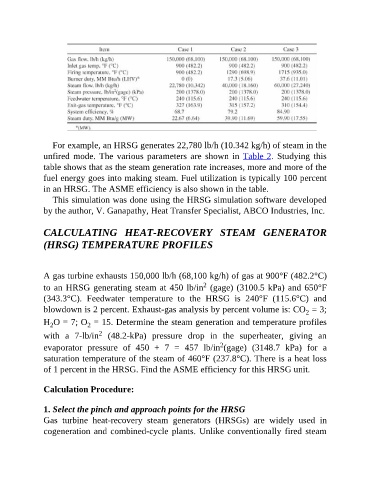

For example, an HRSG generates 22,780 lb/h (10.342 kg/h) of steam in the

unfired mode. The various parameters are shown in Table 2. Studying this

table shows that as the steam generation rate increases, more and more of the

fuel energy goes into making steam. Fuel utilization is typically 100 percent

in an HRSG. The ASME efficiency is also shown in the table.

This simulation was done using the HRSG simulation software developed

by the author, V. Ganapathy, Heat Transfer Specialist, ABCO Industries, Inc.

CALCULATING HEAT-RECOVERY STEAM GENERATOR

(HRSG) TEMPERATURE PROFILES

A gas turbine exhausts 150,000 lb/h (68,100 kg/h) of gas at 900°F (482.2°C)

2

to an HRSG generating steam at 450 lb/in (gage) (3100.5 kPa) and 650°F

(343.3°C). Feedwater temperature to the HRSG is 240°F (115.6°C) and

blowdown is 2 percent. Exhaust-gas analysis by percent volume is: CO = 3;

2

H O = 7; O = 15. Determine the steam generation and temperature profiles

2

2

2

with a 7-lb/in (48.2-kPa) pressure drop in the superheater, giving an

2

evaporator pressure of 450 + 7 = 457 lb/in (gage) (3148.7 kPa) for a

saturation temperature of the steam of 460°F (237.8°C). There is a heat loss

of 1 percent in the HRSG. Find the ASME efficiency for this HRSG unit.

Calculation Procedure:

1. Select the pinch and approach points for the HRSG

Gas turbine heat-recovery steam generators (HRSGs) are widely used in

cogeneration and combined-cycle plants. Unlike conventionally fired steam