Page 208 - Handbook of Energy Engineering Calculations

P. 208

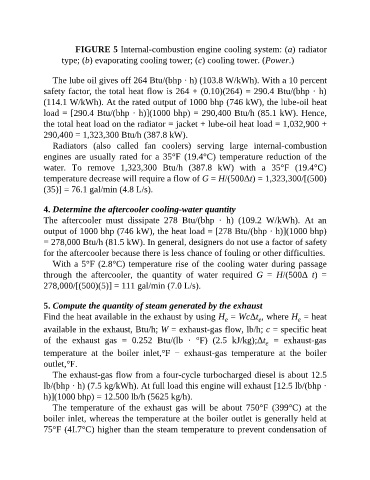

FIGURE 5 Internal-combustion engine cooling system: (a) radiator

type; (b) evaporating cooling tower; (c) cooling tower. (Power.)

The lube oil gives off 264 Btu/(bhp · h) (103.8 W/kWh). With a 10 percent

safety factor, the total heat flow is 264 + (0.10)(264) = 290.4 Btu/(bhp · h)

(114.1 W/kWh). At the rated output of 1000 bhp (746 kW), the lube-oil heat

load = [290.4 Btu/(bhp · h)](1000 bhp) = 290,400 Btu/h (85.1 kW). Hence,

the total heat load on the radiator = jacket + lube-oil heat load = 1,032,900 +

290,400 = 1,323,300 Btu/h (387.8 kW).

Radiators (also called fan coolers) serving large internal-combustion

engines are usually rated for a 35°F (19.4°C) temperature reduction of the

water. To remove 1,323,300 Btu/h (387.8 kW) with a 35°F (19.4°C)

temperature decrease will require a flow of G = H/(500Δt) = 1,323,300/[(500)

(35)] = 76.1 gal/min (4.8 L/s).

4. Determine the aftercooler cooling-water quantity

The aftercooler must dissipate 278 Btu/(bhp · h) (109.2 W/kWh). At an

output of 1000 bhp (746 kW), the heat load = [278 Btu/(bhp · h)](1000 bhp)

= 278,000 Btu/h (81.5 kW). In general, designers do not use a factor of safety

for the aftercooler because there is less chance of fouling or other difficulties.

With a 5°F (2.8°C) temperature rise of the cooling water during passage

through the aftercooler, the quantity of water required G = H/(500Δ t) =

278,000/[(500)(5)] = 111 gal/min (7.0 L/s).

5. Compute the quantity of steam generated by the exhaust

Find the heat available in the exhaust by using H = WcΔt , where H = heat

e

e

e

available in the exhaust, Btu/h; W = exhaust-gas flow, lb/h; c = specific heat

of the exhaust gas = 0.252 Btu/(lb · °F) (2.5 kJ/kg);Δt = exhaust-gas

e

temperature at the boiler inlet,°F − exhaust-gas temperature at the boiler

outlet,°F.

The exhaust-gas flow from a four-cycle turbocharged diesel is about 12.5

lb/(bhp · h) (7.5 kg/kWh). At full load this engine will exhaust [12.5 lb/(bhp ·

h)](1000 bhp) = 12.500 lb/h (5625 kg/h).

The temperature of the exhaust gas will be about 750°F (399°C) at the

boiler inlet, whereas the temperature at the boiler outlet is generally held at

75°F (4I.7°C) higher than the steam temperature to prevent condensation of