Page 378 - Handbook of Energy Engineering Calculations

P. 378

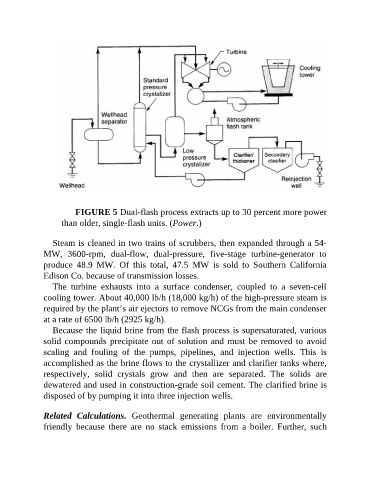

FIGURE 5 Dual-flash process extracts up to 30 percent more power

than older, single-flash units. (Power.)

Steam is cleaned in two trains of scrubbers, then expanded through a 54-

MW, 3600-rpm, dual-flow, dual-pressure, five-stage turbine-generator to

produce 48.9 MW. Of this total, 47.5 MW is sold to Southern California

Edison Co. because of transmission losses.

The turbine exhausts into a surface condenser, coupled to a seven-cell

cooling tower. About 40,000 lb/h (18,000 kg/h) of the high-pressure steam is

required by the plant’s air ejectors to remove NCGs from the main condenser

at a rate of 6500 lb/h (2925 kg/h).

Because the liquid brine from the flash process is supersaturated, various

solid compounds precipitate out of solution and must be removed to avoid

scaling and fouling of the pumps, pipelines, and injection wells. This is

accomplished as the brine flows to the crystallizer and clarifier tanks where,

respectively, solid crystals grow and then are separated. The solids are

dewatered and used in construction-grade soil cement. The clarified brine is

disposed of by pumping it into three injection wells.

Related Calculations. Geothermal generating plants are environmentally

friendly because there are no stack emissions from a boiler. Further, such