Page 404 - Handbook of Energy Engineering Calculations

P. 404

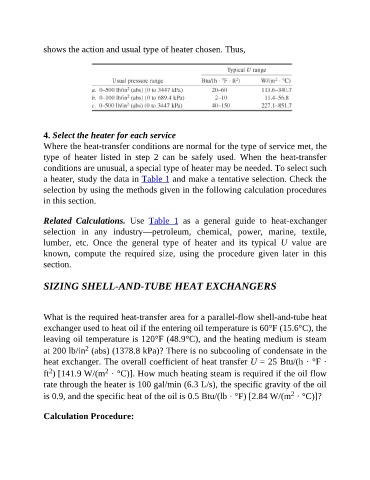

shows the action and usual type of heater chosen. Thus,

4. Select the heater for each service

Where the heat-transfer conditions are normal for the type of service met, the

type of heater listed in step 2 can be safely used. When the heat-transfer

conditions are unusual, a special type of heater may be needed. To select such

a heater, study the data in Table 1 and make a tentative selection. Check the

selection by using the methods given in the following calculation procedures

in this section.

Related Calculations. Use Table 1 as a general guide to heat-exchanger

selection in any industry—petroleum, chemical, power, marine, textile,

lumber, etc. Once the general type of heater and its typical U value are

known, compute the required size, using the procedure given later in this

section.

SIZING SHELL-AND-TUBE HEAT EXCHANGERS

What is the required heat-transfer area for a parallel-flow shell-and-tube heat

exchanger used to heat oil if the entering oil temperature is 60°F (15.6°C), the

leaving oil temperature is 120°F (48.9°C), and the heating medium is steam

2

at 200 lb/in (abs) (1378.8 kPa)? There is no subcooling of condensate in the

heat exchanger. The overall coefficient of heat transfer U = 25 Btu/(h · °F ·

2

2

ft ) [141.9 W/(m · °C)]. How much heating steam is required if the oil flow

rate through the heater is 100 gal/min (6.3 L/s), the specific gravity of the oil

2

is 0.9, and the specific heat of the oil is 0.5 Btu/(lb · °F) [2.84 W/(m · °C)]?

Calculation Procedure: