Page 275 - Handbook of Materials Failure Analysis

P. 275

6 Parametric Accelerated Life Testing 271

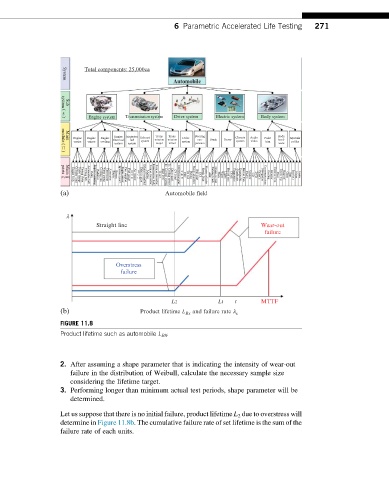

Total components: 25,000ea

Automobile

System

5 system ( ) Sub

Engine system Transmissionsystem Drive system Electric system Body system

Engine Emission Exhaust Trans- Trans- Steering Body

Engine Engine Engine Drive Climate Audio Paint Squeaks

-major -minor cooling electrical fuel system mission mission system sus- Break Power system video trim hard- rattles

Main

module

system system major minor pension ware

17

( )

E E 4

G Air sensor C Exhaust pipe Exhaust manifold Muffler Torque converter Transmission body Torque converter Clutch Shift lever Tr. Control system Tr. Cooling system Drive shaft CV Joint Differential gear W ESC Tie rod Busing Shock absorber Ball joint ECS Break Disk Master cylinder ABS Parking braek Cruise control Horn Wiper Lights Heated seat TPMS Compressor Cond

parts

Main

(25,000) R U D

Pulley

Starter

Battery

Radiator

Alternator

Timing belt

Fuel gauge

Thermostat

Water pump

Engine body

Fuel supplier

Timing chain

Cooling pan

Engine sensor

Turbo charge

Cylinder head

Ignition system

Accessories belt

Engine mounting

(a) Automobile field

l

Straight line Wear-out

failure

Overstress

failure

L2 L1 t MTTF

(b) Product lifetime L and failure rate l s

Bx

FIGURE 11.8

Product lifetime such as automobile L BX .

2. After assuming a shape parameter that is indicating the intensity of wear-out

failure in the distribution of Weibull, calculate the necessary sample size

considering the lifetime target.

3. Performing longer than minimum actual test periods, shape parameter will be

determined.

Let us suppose that there is no initial failure, product lifetime L 2 due to overstress will

determine in Figure 11.8b. The cumulative failure rate of set lifetime is the sum of the

failure rate of each units.