Page 272 - Handbook of Materials Failure Analysis

P. 272

268 CHAPTER 11 The reliability design of mechanical system

Existing products New products Rival products

AB series PA series C series

Compare Compare

Expected problem Comparative advantage for

Existing product

(15 items) for new design performance and reliability

(10 items) (10 items)

Total 35 items

Performance Reliability

(15 items) (20 items)

Usual Special

performance performance Reliability marginal Reliability quantitative

specifications specifications test specifications test specifications

RM (15 items) RQ (5 items)

UP (10 items) SP (5 items)

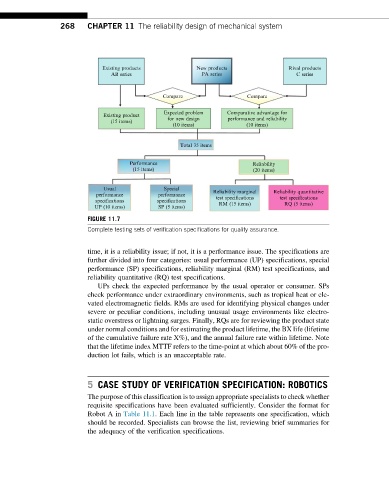

FIGURE 11.7

Complete testing sets of verification specifications for quality assurance.

time, it is a reliability issue; if not, it is a performance issue. The specifications are

further divided into four categories: usual performance (UP) specifications, special

performance (SP) specifications, reliability marginal (RM) test specifications, and

reliability quantitative (RQ) test specifications.

UPs check the expected performance by the usual operator or consumer. SPs

check performance under extraordinary environments, such as tropical heat or ele-

vated electromagnetic fields. RMs are used for identifying physical changes under

severe or peculiar conditions, including unusual usage environments like electro-

static overstress or lightning surges. Finally, RQs are for reviewing the product state

under normal conditions and for estimating the product lifetime, the BX life (lifetime

of the cumulative failure rate X%), and the annual failure rate within lifetime. Note

that the lifetime index MTTF refers to the time-point at which about 60% of the pro-

duction lot fails, which is an unacceptable rate.

5 CASE STUDY OF VERIFICATION SPECIFICATION: ROBOTICS

The purpose of this classification is to assign appropriate specialists to check whether

requisite specifications have been evaluated sufficiently. Consider the format for

Robot A in Table 11.1. Each line in the table represents one specification, which

should be recorded. Specialists can browse the list, reviewing brief summaries for

the adequacy of the verification specifications.