Page 141 - Handbook of Plastics Technologies

P. 141

THERMOSETS

THERMOSETS 3.11

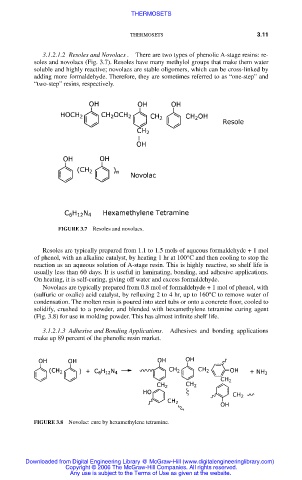

3.1.2.1.2 Resoles and Novolacs . There are two types of phenolic A-stage resins: re-

soles and novolacs (Fig. 3.7). Resoles have many methylol groups that make them water

soluble and highly reactive; novolacs are stable oligomers, which can be cross-linked by

adding more formaldehyde. Therefore, they are sometimes referred to as “one-step” and

“two-step” resins, respectively.

FIGURE 3.7 Resoles and novolacs.

Resoles are typically prepared from 1.1 to 1.5 mols of aqueous formaldehyde + 1 mol

of phenol, with an alkaline catalyst, by heating 1 hr at 100°C and then cooling to stop the

reaction as an aqueous solution of A-stage resin. This is highly reactive, so shelf life is

usually less than 60 days. It is useful in laminating, bonding, and adhesive applications.

On heating, it is self-curing, giving off water and excess formaldehyde.

Novolacs are typically prepared from 0.8 mol of formaldehyde + 1 mol of phenol, with

(sulfuric or oxalic) acid catalyst, by refluxing 2 to 4 hr, up to 160°C to remove water of

condensation. The molten resin is poured into steel tubs or onto a concrete floor, cooled to

solidify, crushed to a powder, and blended with hexamethylene tetramine curing agent

(Fig. 3.8) for use in molding powder. This has almost infinite shelf life.

3.1.2.1.3 Adhesive and Bonding Applications. Adhesives and bonding applications

make up 89 percent of the phenolic resin market.

FIGURE 3.8 Novolac: cure by hexamethylene tetramine.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.