Page 143 - Handbook of Plastics Technologies

P. 143

THERMOSETS

THERMOSETS 3.13

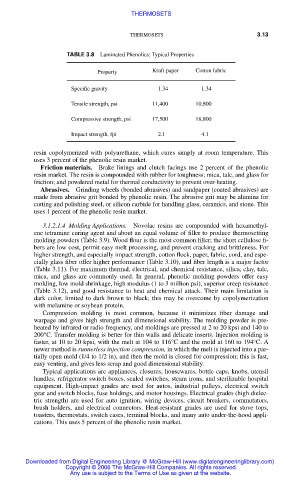

TABLE 3.8 Laminated Phenolics: Typical Properties

Property Kraft paper Cotton fabric

Specific gravity 1.34 1.34

Tensile strength, psi 11,400 10,800

Compressive strength, psi 17,500 18,800

Impact strength, fpi 2.1 4.1

resin copolymerized with polyurethane, which cures simply at room temperature. This

uses 3 percent of the phenolic resin market.

Friction materials. Brake linings and clutch facings use 2 percent of the phenolic

resin market. The resin is compounded with rubber for toughness; mica, talc, and glass for

friction; and powdered metal for thermal conductivity to prevent over-heating.

Abrasives. Grinding wheels (bonded abrasives) and sandpaper (coated abrasives) are

made from abrasive grit bonded by phenolic resin. The abrasive grit may be alumina for

cutting and polishing steel, or silicon carbide for handling glass, ceramics, and stone. This

uses 1 percent of the phenolic resin market.

3.1.2.1.4 Molding Applications. Novolac resins are compounded with hexamethyl-

ene tetramine curing agent and about an equal volume of filler to produce thermosetting

molding powders (Table 3.9). Wood flour is the most common filler; the short cellulose fi-

bers are low cost, permit easy melt processing, and prevent cracking and brittleness. For

higher strength, and especially impact strength, cotton flock, paper, fabric, cord, and espe-

cially glass fiber offer higher performance (Table 3.10), and fiber length is a major factor

(Table 3.11). For maximum thermal, electrical, and chemical resistance, silica, clay, talc,

mica, and glass are commonly used. In general, phenolic molding powders offer easy

molding, low mold shrinkage, high modulus (1 to 3 million psi), superior creep resistance

(Table 3.12), and good resistance to heat and chemical attack. Their main limitation is

dark color, limited to dark brown to black; this may be overcome by copolymerization

with melamine or soybean protein.

Compression molding is most common, because it minimizes fiber damage and

warpage and gives high strength and dimensional stability. The molding powder is pre-

heated by infrared or radio frequency, and moldings are pressed at 2 to 20 kpsi and 140 to

200°C. Transfer molding is better for thin walls and delicate inserts. Injection molding is

faster, at 10 to 20 kpsi, with the melt at 104 to 116°C and the mold at 160 to 194°C. A

newer method is runnerless injection compression, in which the melt is injected into a par-

tially open mold (1/4 to 1/2 in), and then the mold is closed for compression; this is fast,

easy venting, and gives less scrap and good dimensional stability.

Typical applications are appliances, closures, housewares, bottle caps, knobs, utensil

handles, refrigerator switch boxes, sealed switches, steam irons, and sterilizable hospital

equipment. High-impact grades are used for autos, industrial pulleys, electrical switch

gear and switch blocks, fuse holdings, and motor housings. Electrical grades (high dielec-

tric strength) are used for auto ignition, wiring devices, circuit breakers, commutators,

brush holders, and electrical connectors. Heat-resistant grades are used for stove tops,

toasters, thermostats, switch cases, terminal blocks, and many auto under-the-hood appli-

cations. This uses 5 percent of the phenolic resin market.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.