Page 145 - Handbook of Plastics Technologies

P. 145

THERMOSETS

THERMOSETS 3.15

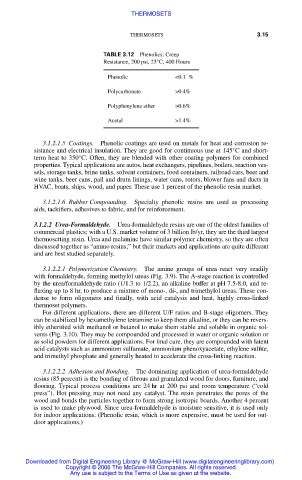

TABLE 3.12 Phenolics: Creep

Resistance, 200 psi, 23°C, 400 Hours

Phenolic <0.1 %

Polycarbonate >0.4%

Polyphenylene ether >0.6%

Acetal >1.4%

3.1.2.1.5 Coatings. Phenolic coatings are used on metals for heat and corrosion re-

sistance and electrical insulation. They are good for continuous use at 145°C and short-

term heat to 350°C. Often, they are blended with other coating polymers for combined

properties. Typical applications are autos, heat exchangers, pipelines, boilers, reaction ves-

sels, storage tanks, brine tanks, solvent containers, food containers, railroad cars, beer and

wine tanks, beer cans, pail and drum linings, water cans, rotors, blower fans and ducts in

HVAC, boats, ships, wood, and paper. These use 1 percent of the phenolic resin market.

3.1.2.1.6 Rubber Compounding. Specialty phenolic resins are used as processing

aids, tackifiers, adhesives to fabric, and for reinforcement.

3.1.2.2 Urea-Formaldehyde. Urea-formaldehyde resins are one of the oldest families of

commercial plastics; with a U.S. market volume of 3 billion lb/yr, they are the third largest

thermosetting resin. Urea and melamine have similar polymer chemistry, so they are often

discussed together as “amino resins;” but their markets and applications are quite different

and are best studied separately.

3.1.2.2.1 Polymerization Chemistry. The amine groups of urea react very readily

with formaldehyde, forming methylol ureas (Fig. 3.9). The A-stage reaction is controlled

by the urea/formaldehyde ratio (1/1.3 to 1/2.2), an alkaline buffer at pH 7.5-8.0, and re-

fluxing up to 8 hr, to produce a mixture of mono-, di-, and trimethylol ureas. These con-

dense to form oligomers and finally, with acid catalysis and heat, highly cross-linked

thermoset polymers.

For different applications, there are different U/F ratios and B-stage oligomers. They

can be stabilized by hexamethylene tetramine to keep them alkaline, or they can be revers-

ibly etherified with methanol or butanol to make them stable and soluble in organic sol-

vents (Fig. 3.10). They may be compounded and processed in water or organic solution or

as solid powders for different applications. For final cure, they are compounded with latent

acid catalysts such as ammonium sulfamate, ammonium phenoxyacetate, ethylene sulfite,

and trimethyl phosphate and generally heated to accelerate the cross-linking reaction.

3.1.2.2.2 Adhesion and Bonding. The dominating application of urea-formaldehyde

resins (85 percent) is the bonding of fibrous and granulated wood for doors, furniture, and

flooring. Typical process conditions are 24 hr at 200 psi and room temperature (“cold

press”). Hot pressing may not need any catalyst. The resin penetrates the pores of the

wood and bonds the particles together to form strong isotropic boards. Another 4 percent

is used to make plywood. Since urea-formaldehyde is moisture sensitive, it is used only

for indoor applications. (Phenolic resin, which is more expensive, must be used for out-

door applications.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.