Page 148 - Handbook of Plastics Technologies

P. 148

THERMOSETS

3.18 CHAPTER 3

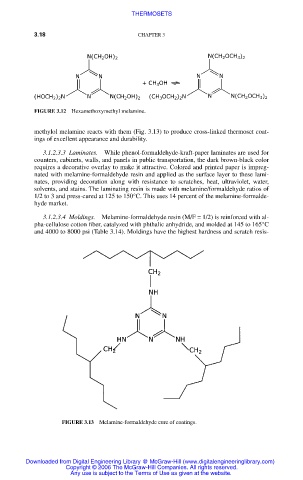

FIGURE 3.12 Hexamethoxymethyl melamine.

methylol melamine reacts with them (Fig. 3.13) to produce cross-linked thermoset coat-

ings of excellent appearance and durability.

3.1.2.3.3 Laminates. While phenol-formaldehyde-kraft-paper laminates are used for

counters, cabinets, walls, and panels in public transportation, the dark brown-black color

requires a decorative overlay to make it attractive. Colored and printed paper is impreg-

nated with melamine-formaldehyde resin and applied as the surface layer to these lami-

nates, providing decoration along with resistance to scratches, heat, ultraviolet, water,

solvents, and stains. The laminating resin is made with melamine/formaldehyde ratios of

1/2 to 3 and press-cured at 125 to 150°C. This uses 14 percent of the melamine-formalde-

hyde market.

3.1.2.3.4 Moldings. Melamine-formaldehyde resin (M/F = 1/2) is reinforced with al-

pha-cellulose cotton fiber, catalyzed with phthalic anhydride, and molded at 145 to 165°C

and 4000 to 8000 psi (Table 3.14). Moldings have the highest hardness and scratch resis-

FIGURE 3.13 Melamine-formaldehyde cure of coatings.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.