Page 299 - Handbook of Plastics Technologies

P. 299

ELASTOMERS

ELASTOMERS 4.91

4.5.5.3 Molding. A molding process is used for the production of many types of prod-

ucts, including shoe soles and heals, gaskets and seals, suction cups, bottle stops, tires, and

others. There are basically three types of molding: compression molding, transfer molding

(Fig. 4.33), and injection molding (Fig. 4.34). Vulcanization is accomplished in the heated

mold in all three processes.

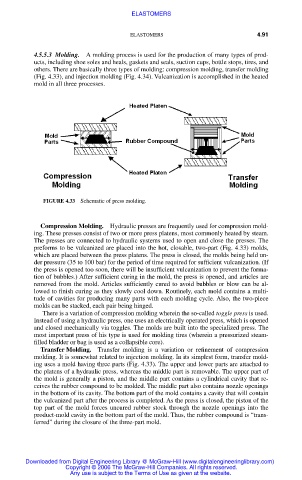

FIGURE 4.33 Schematic of press molding.

Compression Molding. Hydraulic presses are frequently used for compression mold-

ing. These presses consist of two or more press platens, most commonly heated by steam.

The presses are connected to hydraulic systems used to open and close the presses. The

preforms to be vulcanized are placed into the hot, closable, two-part (Fig. 4.33) molds,

which are placed between the press platens. The press is closed, the molds being held un-

der pressure (35 to 100 bar) for the period of time required for sufficient vulcanization. (If

the press is opened too soon, there will be insufficient vulcanization to prevent the forma-

tion of bubbles.) After sufficient curing in the mold, the press is opened, and articles are

removed from the mold. Articles sufficiently cured to avoid bubbles or blow can be al-

lowed to finish curing as they slowly cool down. Routinely, each mold contains a multi-

tude of cavities for producing many parts with each molding cycle. Also, the two-piece

molds can be stacked, each pair being hinged.

There is a variation of compression molding wherein the so-called toggle press is used.

Instead of using a hydraulic press, one uses an electrically operated press, which is opened

and closed mechanically via toggles. The molds are built into the specialized press. The

most important press of his type is used for molding tires (wherein a pressurized steam-

filled bladder or bag is used as a collapsible core).

Transfer Molding. Transfer molding is a variation or refinement of compression

molding. It is somewhat related to injection molding. In its simplest form, transfer mold-

ing uses a mold having three parts (Fig. 4.33). The upper and lower parts are attached to

the platens of a hydraulic press, whereas the middle part is removable. The upper part of

the mold is generally a piston, and the middle part contains a cylindrical cavity that re-

ceives the rubber compound to be molded. The middle part also contains nozzle openings

in the bottom of its cavity. The bottom part of the mold contains a cavity that will contain

the vulcanized part after the process is completed. As the press is closed, the piston of the

top part of the mold forces uncured rubber stock through the nozzle openings into the

product-mold cavity in the bottom part of the mold. Thus, the rubber compound is “trans-

ferred” during the closure of the three-part mold.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.