Page 304 - Handbook of Plastics Technologies

P. 304

ELASTOMERS

4.96 CHAPTER 4

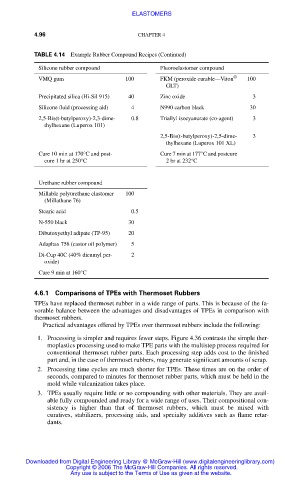

TABLE 4.14 Example Rubber Compound Recipes (Continued)

Silicone rubber compound Fluoroelastomer compound

®

VMQ gum 100 FKM (peroxide curable—Viton 100

GLT)

Precipitated silica (Hi-Sil 915) 40 Zinc oxide 3

Silicone fluid (processing aid) 4 N990 carbon black 30

2,5-Bis(t-butylperoxy)-2,3-dime- 0.8 Triallyl isocyanurate (co-agent) 3

thylhexane (Luperox 101)

2,5-Bis(t-butylperoxy)-2,5-dime- 3

thylhexane (Luperox 101 XL)

Cure 10 min at 170°C and post- Cure 7 min at 177°C and postcure

cure 1 hr at 250°C 2 hr at 232°C

Urethane rubber compound

Millable polyurethane elastomer 100

(Millathane 76)

Stearic acid 0.5

N-550 black 30

Dibutoxyethyl adipate (TP-95) 20

Adaphax 758 (castor oil polymer) 5

Di-Cup 40C (40% dicumyl per- 2

oxide)

Cure 9 min at 160°C

4.6.1 Comparisons of TPEs with Thermoset Rubbers

TPEs have replaced thermoset rubber in a wide range of parts. This is because of the fa-

vorable balance between the advantages and disadvantages of TPEs in comparison with

thermoset rubbers.

Practical advantages offered by TPEs over thermoset rubbers include the following:

1. Processing is simpler and requires fewer steps. Figure 4.36 contrasts the simple ther-

moplastics processing used to make TPE parts with the multistep process required for

conventional thermoset rubber parts. Each processing step adds cost to the finished

part and, in the case of thermoset rubbers, may generate significant amounts of scrap.

2. Processing time cycles are much shorter for TPEs. These times are on the order of

seconds, compared to minutes for thermoset rubber parts, which must be held in the

mold while vulcanization takes place.

3. TPEs usually require little or no compounding with other materials. They are avail-

able fully compounded and ready for a wide range of uses. Their compositional con-

sistency is higher than that of thermoset rubbers, which must be mixed with

curatives, stabilizers, processing aids, and specialty additives such as flame retar-

dants.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.