Page 309 - Handbook of Plastics Technologies

P. 309

ELASTOMERS

ELASTOMERS 4.101

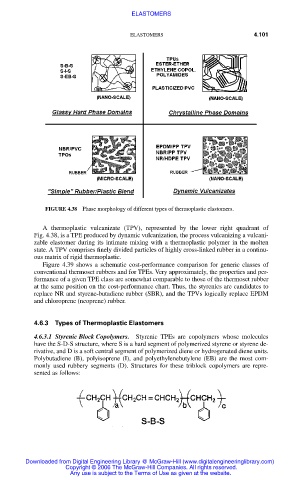

FIGURE 4.38 Phase morphology of different types of thermoplastic elastomers.

A thermoplastic vulcanizate (TPV), represented by the lower right quadrant of

Fig. 4.38, is a TPE produced by dynamic vulcanization, the process vulcanizing a vulcani-

zable elastomer during its intimate mixing with a thermoplastic polymer in the molten

state. A TPV comprises finely divided particles of highly cross-linked rubber in a continu-

ous matrix of rigid thermoplastic.

Figure 4.39 shows a schematic cost-performance comparison for generic classes of

conventional thermoset rubbers and for TPEs. Very approximately, the properties and per-

formance of a given TPE class are somewhat comparable to those of the thermoset rubber

at the same position on the cost-performance chart. Thus, the styrenics are candidates to

replace NR and styrene-butadiene rubber (SBR), and the TPVs logically replace EPDM

and chloroprene (neoprene) rubber.

4.6.3 Types of Thermoplastic Elastomers

4.6.3.1 Styrenic Block Copolymers. Styrenic TPEs are copolymers whose molecules

have the S-D-S structure, where S is a hard segment of polymerized styrene or styrene de-

rivative, and D is a soft central segment of polymerized diene or hydrogenated diene units.

Polybutadiene (B), polyisoprene (I), and polyethylenebutylene (EB) are the most com-

monly used rubbery segments (D). Structures for these triblock copolymers are repre-

sented as follows:

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.