Page 308 - Handbook of Plastics Technologies

P. 308

ELASTOMERS

4.100 CHAPTER 4

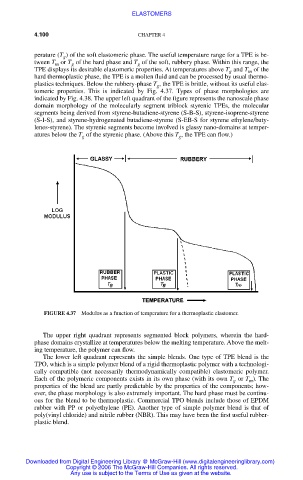

perature (T ) of the soft elastomeric phase. The useful temperature range for a TPE is be-

g

tween T or T of the hard phase and T of the soft, rubbery phase. Within this range, the

g

m

g

TPE displays its desirable elastomeric properties. At temperatures above T and T of the

g

m

hard thermoplastic phase, the TPE is a molten fluid and can be processed by usual thermo-

plastics techniques. Below the rubbery-phase T , the TPE is brittle, without its useful elas-

g

tomeric properties. This is indicated by Fig. 4.37. Types of phase morphologies are

indicated by Fig. 4.38. The upper left quadrant of the figure represents the nanoscale phase

domain morphology of the molecularly segment triblock styrenic TPEs, the molecular

segments being derived from styrene-butadiene-styrene (S-B-S), styrene-isoprene-styrene

(S-I-S), and styrene-hydrogenated butadiene-styrene (S-EB-S for styrene ethylene/buty-

lenes-styrene). The styrenic segments become involved is glassy nano-domains at temper-

atures below the T of the styrenic phase. (Above this T , the TPE can flow.)

g

g

FIGURE 4.37 Modulus as a function of temperature for a thermoplastic elastomer.

The upper right quadrant represents segmented block polymers, wherein the hard-

phase domains crystallize at temperatures below the melting temperature. Above the melt-

ing temperature, the polymer can flow.

The lower left quadrant represents the simple blends. One type of TPE blend is the

TPO, which is a simple polymer blend of a rigid thermoplastic polymer with a technologi-

cally compatible (not necessarily thermodynamically compatible) elastomeric polymer.

Each of the polymeric components exists in its own phase (with its own T or T ). The

m

g

properties of the blend are partly predictable by the properties of the components; how-

ever, the phase morphology is also extremely important. The hard phase must be continu-

ous for the blend to be thermoplastic. Commercial TPO blends include those of EPDM

rubber with PP or polyethylene (PE). Another type of simple polymer blend is that of

poly(vinyl chloride) and nitrile rubber (NBR). This may have been the first useful rubber-

plastic blend.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.