Page 82 - Handbook of Plastics Technologies

P. 82

THERMOPLASTICS

2.22 CHAPTER 2

as a result of the oriented liquid crystal behavior, the properties will be anisotropic. The

172

designer must be aware of this to properly design the part and gate the molds. The phe-

173

nyl ring also helps increase the heat distortion temperature.

The basic building blocks for liquid crystal polyesters are p-hydroxybenzoic acid,

terephthalic acid, and hydroquinone. Unfortunately, the use of these monomers alone

gives materials that are difficult to process with very high melting points. The polymers

often degraded before melting. 174 Various techniques have been developed to give materi-

als with lower melting points and better processing behavior. Some methods include the

incorporation of flexible units in the chain (copolymerizing with ethylene glycol), the ad-

dition of nonlinear rigid structures, and the addition of aromatic groups to the side of the

chain. 175

Liquid crystal polymers based on these techniques include Victrex (ICI), Vectra (Hoe-

scht), and Xydar (Amoco). Xydar is based on terephthalic acid, p-hydroxybenzoic acid,

and p,p´-dihydroxybiphenyl, while Vectra is based on p-hydroxybenzoic acid and hydrox-

ynaphthoic acid. 176 These materials are known for their high temperature resistance, and

particularly heat distortion temperature. The heat distortion temperature can vary from 170

to 350°C. They also have excellent mechanical properties, especially in the flow direction.

For example, the tensile strength varies from 165 to 230 Mpa, the flexural strength varies

from 169 to 256 Mpa, and the flexural modulus varies from 9 to 12.5 Gpa. 177 Filled mate-

rials exhibit even higher values. LCPs are also known for good solvent resistance and low

water absorption compared to other heat-resistant polymers. They have good electrical in-

sulation properties, low flammability with a limiting oxygen index in the range of 35 to 40,

but a high specific gravity (about 1.40). 178 LCPs show little dimensional change when ex-

posed to high temperatures and a low coefficient of thermal expansion. 179

These materials can be high priced and often exhibit poor abrasion resistance due to

the oriented nature of the polymer chains. 180 Surface fibrillation may occur quite eas-

ily. 181 The materials are processable on a variety of conventional equipment. Process tem-

peratures are normally below 350°C, although some materials may need to be processed at

higher temperatures. They generally have low melt viscosity as a result of their ordered

melt and should be dried before use to avoid degradation. 182 LCPs can be injection

molded on conventional equipment, and regrind may be used. Mold release is generally

not required. 183 Part design for LCPs requires careful consideration of the anisotropic na-

ture of the polymer. Weld lines can be very weak if the melt meets in a “butt” type of weld

line. Other types of weld lines show better strength. 184

Liquid crystal polymers are used in automotive, electrical, chemical processing, and

185

household applications. One application is for oven and microwave cookware. Because

of their higher costs, the material is used only in applications where its superior perfor-

mance justifies the additional expense.

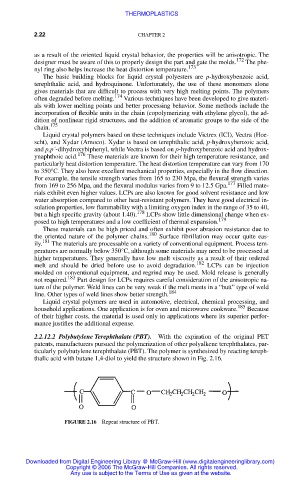

2.2.12.2 Polybutylene Terephthalate (PBT). With the expiration of the original PET

patents, manufacturers pursued the polymerization of other polyalkene terephthalates, par-

ticularly polybutylene terephthalate (PBT). The polymer is synthesized by reacting tereph-

thalic acid with butane 1,4-diol to yield the structure shown in Fig. 2.16.

FIGURE 2.16 Repeat structure of PBT.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.