Page 80 - Handbook of Plastics Technologies

P. 80

THERMOPLASTICS

2.20 CHAPTER 2

Applications where PC is blended with ABS increase the heat distortion temperature of

the ABS and improve the low-temperature impact strength of PC. The favorable ease of

processing and improved economics make PC/ABS blends well suited for thin-walled

electronic housing applications such as laptop computers. Blends with PBT are useful for

improving the chemical resistance of PC to petroleum products and its low-temperature

impact strength. PC alone is widely used as vacuum cleaner housings, household appli-

ance housings, and power tools. These are arenas where PC’s high impact strength, heat

resistance, durability, and high-quality finish justify its expense. It is also used in safety

helmets, riot shields, aircraft canopies, traffic light lens housings, and automotive battery

cases. Design engineers take care not to design with tight radii where PC’s tendency to

stress crack could be a hindrance. PC cannot withstand constant exposure to hot water and

can absorb 0.2 percent of its weight of water at 33°C and 65 percent relative humidity.

This does not impair its mechanical properties but, at levels greater than 0.01 percent, pro-

cessing results in streaks and blistering.

2.2.12 Polyester Thermoplastics

The broad class of organic chemicals called polyesters are characterized by the fact that

they contain an ester linkage,

and may have either aliphatic or aromatic hydrocarbon units. As an introduction, Table 2.4

offers some selected thermal and mechanical properties as a means of comparing polybu-

tylene terephthalate (PBT), polycyclohexylenedimethylene terephthalate (PCT), and

poly(ethylene terephthalate) (PET).

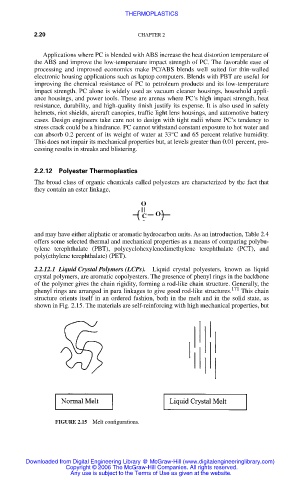

2.2.12.1 Liquid Crystal Polymers (LCPs). Liquid crystal polyesters, known as liquid

crystal polymers, are aromatic copolyesters. The presence of phenyl rings in the backbone

of the polymer gives the chain rigidity, forming a rod-like chain structure. Generally, the

171

phenyl rings are arranged in para linkages to give good rod-like structures. This chain

structure orients itself in an ordered fashion, both in the melt and in the solid state, as

shown in Fig. 2.15. The materials are self-reinforcing with high mechanical properties, but

FIGURE 2.15 Melt configurations.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.