Page 75 - Handbook of Plastics Technologies

P. 75

THERMOPLASTICS

THERMOPLASTICS 2.15

able is Barex (BP Chemicals). The copolymer has better barrier properties than both

131

polypropylene and polyethylene terephthalate. Acrylonitrile is also used with butadiene

and styrene to form ABS polymers. Unlike the homopolymer, copolymers can be pro-

132

cessed by many methods, including extrusion, blow molding, and injection molding.

Acrylonitrile is often copolymerized with other monomers to form fibers. Copolymer-

ization with monomers such as vinyl acetate, vinyl pyrrolidone, and vinyl esters gives the

fibers the ability to be dyed using normal textile dyes. The copolymer generally contains at

least 85 percent acrylonitrile. 133 Acrylic fibers have good abrasion resistance, flex life, and

toughness, and high strength. They have good resistance to stains and moisture.

Modacrylic fibers contain between 35 and 85 percent acrylonitrile. 134

Most of the acrylonitrile consumed goes into the production of fibers. Copolymers also

consume large amounts of acrylonitrile. In addition to their use as fibers, polyacrylonitrile

polymers can be used as precursors to carbon fibers.

2.2.7 Polyamide-imide (PAI)

Polyamide-imide (PAI) is a high-temperature amorphous thermoplastic that has been

135

available since the 1970s under the trade name of Torlon. PAI can be produced from the

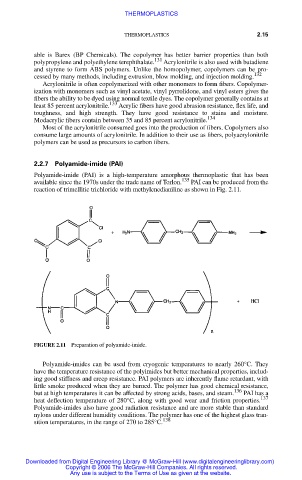

reaction of trimellitic trichloride with methylenedianiline as shown in Fig. 2.11.

FIGURE 2.11 Preparation of polyamide-imide.

Polyamide-imides can be used from cryogenic temperatures to nearly 260°C. They

have the temperature resistance of the polyimides but better mechanical properties, includ-

ing good stiffness and creep resistance. PAI polymers are inherently flame retardant, with

little smoke produced when they are burned. The polymer has good chemical resistance,

136

but at high temperatures it can be affected by strong acids, bases, and steam. PAI has a

137

heat deflection temperature of 280°C, along with good wear and friction properties.

Polyamide-imides also have good radiation resistance and are more stable than standard

nylons under different humidity conditions. The polymer has one of the highest glass tran-

138

sition temperatures, in the range of 270 to 285°C.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.