Page 74 - Handbook of Plastics Technologies

P. 74

THERMOPLASTICS

2.14 CHAPTER 2

copolymer with a T about 160°C, and a lower water absorption and density than the Tro-

g

120

gamid T. The aromatic polyamides are tough materials and compete with polycarbon-

ate, poly(methyl methacrylate) and polysulfone. These materials are used in applications

requiring transparency. They have been used for solvent containers, flow meter parts, and

121

clear housings for electrical equipment. In the 1980s, a polyarylamide marketed as

IXEF was introduced, and Solvay targets it for the injection molding market, particularly

122

high-temperature automotive applications.

An example of a crystallizable aromatic polyamide is poly-m-xylylene adipamide. It

has a T near 85 to 100°C and a T of 235 to 240°C. 123 To obtain high heat deflection tem-

m

g

perature, the filled grades are normally sold. Applications include gears, electrical plugs,

and mowing machine components. 124

Crystalline aromatic polyamides are also used in fiber applications. An example of this

®

type of material is Kevlar , a high-strength fiber used in bulletproof vests and composite

®

structures. A similar material, which can be processed more easily, is Nomex . It can be

used to give flame retardance to cloth when used as a coating. 125

2.2.6 Polyacrylonitrile

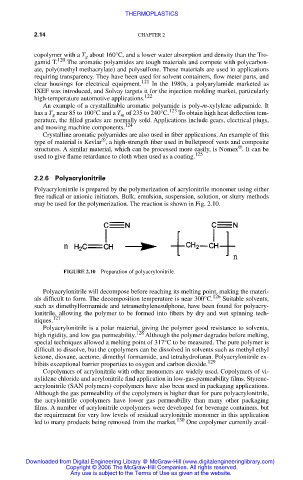

Polyacrylonitrile is prepared by the polymerization of acrylonitrile monomer using either

free radical or anionic initiators. Bulk, emulsion, suspension, solution, or slurry methods

may be used for the polymerization. The reaction is shown in Fig. 2.10.

FIGURE 2.10 Preparation of polyacrylonitrile.

Polyacrylonitrile will decompose before reaching its melting point, making the materi-

als difficult to form. The decomposition temperature is near 300°C. 126 Suitable solvents,

such as dimethylformamide and tetramethylenesulphone, have been found for polyacry-

lonitrile, allowing the polymer to be formed into fibers by dry and wet spinning tech-

niques. 127

Polyacrylonitrile is a polar material, giving the polymer good resistance to solvents,

128

high rigidity, and low gas permeability. Although the polymer degrades before melting,

special techniques allowed a melting point of 317°C to be measured. The pure polymer is

difficult to dissolve, but the copolymers can be dissolved in solvents such as methyl ethyl

ketone, dioxane, acetone, dimethyl formamide, and tetrahydrofuran. Polyacrylonitrile ex-

129

hibits exceptional barrier properties to oxygen and carbon dioxide.

Copolymers of acrylonitrile with other monomers are widely used. Copolymers of vi-

nylidene chloride and acrylonitrile find application in low-gas-permeability films. Styrene-

acrylonitrile (SAN polymers) copolymers have also been used in packaging applications.

Although the gas permeability of the copolymers is higher than for pure polyacrylonitrile,

the acrylonitrile copolymers have lower gas permeability than many other packaging

films. A number of acrylonitrile copolymers were developed for beverage containers, but

the requirement for very low levels of residual acrylonitrile monomer in this application

130

led to many products being removed from the market. One copolymer currently avail-

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.