Page 100 - Handbook of Properties of Textile and Technical Fibres

P. 100

Properties of wool 81

100 2.5

Stress at 15% strain (MPa) 60 1.5 Modulus (GPa)

2.0

80

40

1.0

20

0.0

0 0.5

0 50 100 150 200 250

Stress at break (MPa)

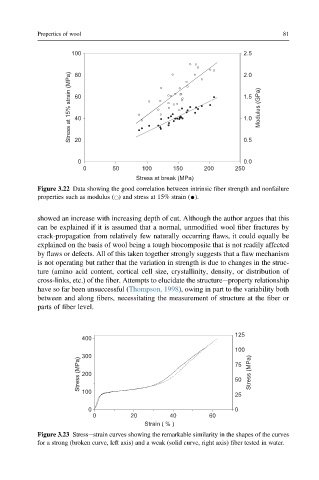

Figure 3.22 Data showing the good correlation between intrinsic fiber strength and nonfailure

properties such as modulus (

) and stress at 15% strain (C).

showed an increase with increasing depth of cut. Although the author argues that this

can be explained if it is assumed that a normal, unmodified wool fiber fractures by

crack-propagation from relatively few naturally occurring flaws, it could equally be

explained on the basis of wool being a tough biocomposite that is not readily affected

by flaws or defects. All of this taken together strongly suggests that a flaw mechanism

is not operating but rather that the variation in strength is due to changes in the struc-

ture (amino acid content, cortical cell size, crystallinity, density, or distribution of

cross-links, etc.) of the fiber. Attempts to elucidate the structureeproperty relationship

have so far been unsuccessful (Thompson, 1998), owing in part to the variability both

between and along fibers, necessitating the measurement of structure at the fiber or

parts of fiber level.

125

400

100

300 75

Stress (MPa) 200 50 Stress (MPa)

100

0

0 25

0 20 40 60

Strain ( % )

Figure 3.23 Stressestrain curves showing the remarkable similarity in the shapes of the curves

for a strong (broken curve, left axis) and a weak (solid curve, right axis) fiber tested in water.