Page 175 - Handbook of Properties of Textile and Technical Fibres

P. 175

152 Handbook of Properties of Textile and Technical Fibres

Silk moth cocoon

Water washing

Dissolution-dialyse

Bave

« Solution »

Industrial yarn

Electrospinning

Weaving Degumming

or and dying or evaporation

- optional -

Textile Regenerated silk

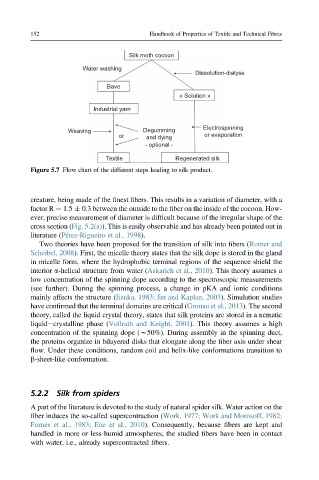

Figure 5.7 Flow chart of the different steps leading to silk product.

creature, being made of the finest fibers. This results in a variation of diameter, with a

factor R ¼ 1.5 0.3 between the outside to the fiber on the inside of the cocoon. How-

ever, precise measurement of diameter is difficult because of the irregular shape of the

cross section (Fig. 5.2(a)). This is easily observable and has already been pointed out in

literature (Pérez-Rigueiro et al., 1998).

Two theories have been proposed for the transition of silk into fibers (Romer and

Scheibel, 2008). First, the micelle theory states that the silk dope is stored in the gland

in micelle form, where the hydrophobic terminal regions of the sequence shield the

interior a-helical structure from water (Askarieh et al., 2010). This theory assumes a

low concentration of the spinning dope according to the spectroscopic measurements

(see further). During the spinning process, a change in pKA and ionic conditions

mainly affects the structure (Iizuka, 1983; Jin and Kaplan, 2003). Simulation studies

have confirmed that the terminal domains are critical (Gronau et al., 2013). The second

theory, called the liquid crystal theory, states that silk proteins are stored in a nematic

liquidecrystalline phase (Vollrath and Knight, 2001). This theory assumes a high

concentration of the spinning dope (w50%). During assembly in the spinning duct,

the proteins organize in bilayered disks that elongate along the fiber axis under shear

flow. Under these conditions, random coil and helix-like conformations transition to

b-sheet-like conformation.

5.2.2 Silk from spiders

A part of the literature is devoted to the study of natural spider silk. Water action on the

fiber induces the so-called supercontraction (Work, 1977; Work and Morosoff, 1982;

Fornes et al., 1983; Ene et al., 2010). Consequently, because fibers are kept and

handled in more or less humid atmospheres, the studied fibers have been in contact

with water, i.e., already supercontracted fibers.