Page 185 - Handbook of Properties of Textile and Technical Fibres

P. 185

162 Handbook of Properties of Textile and Technical Fibres

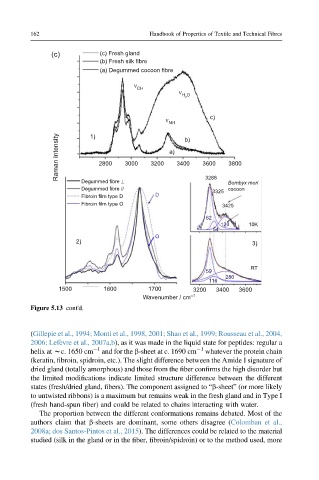

(c) (c) Fresh gland

(b) Fresh silk fibre

(a) Degummed cocoon fibre

ν

CH

ν

H O

2

ν NH c)

1)

Raman intensity 2800 3000 3200 a) 3400 3600 3800

b)

Degummed fibre ⊥

cocoon

Degummed fibre // 3288 Bombyx mori

3325

Fibroin film type D D

Fibroin film type O 3425

62

120 10K

54

O

2) 3)

RT

59

280

116

1500 1600 1700 3200 3400 3600

Wavenumber / cm –1

Figure 5.13 cont'd.

(Gillepie et al., 1994; Monti et al., 1998, 2001; Shao et al., 1999; Rousseau et al., 2004,

2006; Lef evre et al., 2007a,b), as it was made in the liquid state for peptides: regular a

helix at wc. 1650 cm 1 and for the b-sheet at c. 1690 cm 1 whatever the protein chain

(keratin, fibroin, spidroin, etc.). The slight difference between the Amide I signature of

dried gland (totally amorphous) and those from the fiber confirms the high disorder but

the limited modifications indicate limited structure difference between the different

states (fresh/dried gland, fibers). The component assigned to “b-sheet” (or more likely

to untwisted ribbons) is a maximum but remains weak in the fresh gland and in Type I

(fresh hand-spun fiber) and could be related to chains interacting with water.

The proportion between the different conformations remains debated. Most of the

authors claim that b-sheets are dominant, some others disagree (Colomban et al.,

2008a; dos Santos-Pintos et al., 2015). The differences could be related to the material

studied (silk in the gland or in the fiber, fibroin/spidroin) or to the method used, more