Page 31 - Handbook of Properties of Textile and Technical Fibres

P. 31

12 Handbook of Properties of Textile and Technical Fibres

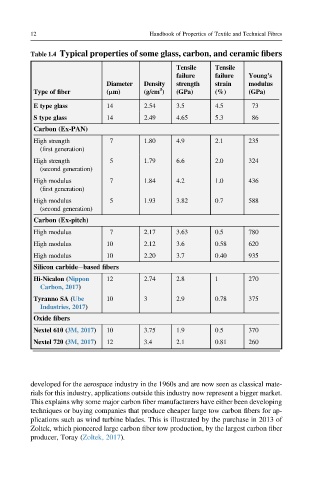

Table 1.4 Typical properties of some glass, carbon, and ceramic fibers

Tensile Tensile

failure failure Young’s

Diameter Density strength strain modulus

3

Type of fiber (mm) (g/cm ) (GPa) (%) (GPa)

E type glass 14 2.54 3.5 4.5 73

S type glass 14 2.49 4.65 5.3 86

Carbon (Ex-PAN)

High strength 7 1.80 4.9 2.1 235

(first generation)

High strength 5 1.79 6.6 2.0 324

(second generation)

High modulus 7 1.84 4.2 1.0 436

(first generation)

High modulus 5 1.93 3.82 0.7 588

(second generation)

Carbon (Ex-pitch)

High modulus 7 2.17 3.63 0.5 780

High modulus 10 2.12 3.6 0.58 620

High modulus 10 2.20 3.7 0.40 935

Silicon carbideebased fibers

Hi-Nicalon (Nippon 12 2.74 2.8 1 270

Carbon, 2017)

Tyranno SA (Ube 10 3 2.9 0.78 375

Industries, 2017)

Oxide fibers

Nextel 610 (3M, 2017) 10 3.75 1.9 0.5 370

Nextel 720 (3M, 2017) 12 3.4 2.1 0.81 260

developed for the aerospace industry in the 1960s and are now seen as classical mate-

rials for this industry, applications outside this industry now represent a bigger market.

This explains why some major carbon fiber manufacturers have either been developing

techniques or buying companies that produce cheaper large tow carbon fibers for ap-

plications such as wind turbine blades. This is illustrated by the purchase in 2013 of

Zoltek, which pioneered large carbon fiber tow production, by the largest carbon fiber

producer, Toray (Zoltek, 2017).