Page 364 - Handbook of Properties of Textile and Technical Fibres

P. 364

Regenerated cellulosic fibers 337

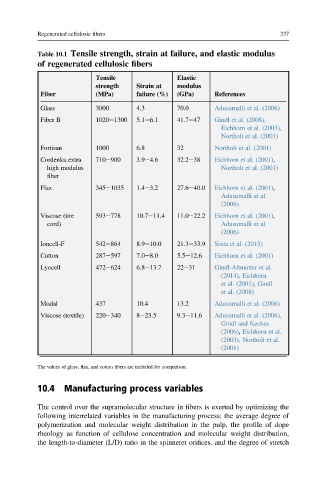

Table 10.1 Tensile strength, strain at failure, and elastic modulus

of regenerated cellulosic fibers

Tensile Elastic

strength Strain at modulus

Fiber (MPa) failure (%) (GPa) References

Glass 3000 4.3 70.0 Adusumalli et al. (2006)

Fiber B 1020e1300 5.1e6.1 41.7e47 Gindl et al. (2008),

Eichhorn et al. (2003),

Northolt et al. (2001)

Fortisan 1000 6.8 32 Northolt et al. (2001)

Cordenka extra 710e900 3.9e4.6 32.2e38 Eichhorn et al. (2001),

high modulus Northolt et al. (2001)

fiber

Flax 345e1035 1.4e3.2 27.6e40.0 Eichhorn et al. (2001),

Adusumalli et al.

(2006)

Viscose (tire 593e778 10.7e11.4 11.0e22.2 Eichhorn et al. (2001),

cord) Adusumalli et al.

(2006)

Ioncell-F 542e864 8.9e10.0 21.3e33.9 Sixta et al. (2015)

Cotton 287e597 7.0e8.0 5.5e12.6 Eichhorn et al. (2001)

Lyocell 472e624 6.8e13.7 22e31 Gindl-Altmutter et al.

(2014), Eichhorn

et al. (2001), Gindl

et al. (2008)

Modal 437 10.4 13.2 Adusumalli et al. (2006)

Viscose (textile) 220e340 8e23.5 9.3e11.6 Adusumalli et al. (2006),

Gindl and Keckes

(2006), Eichhorn et al.

(2003), Northolt et al.

(2001)

The values of glass, flax, and cotton fibers are included for comparison.

10.4 Manufacturing process variables

The control over the supramolecular structure in fibers is exerted by optimizing the

following interrelated variables in the manufacturing process: the average degree of

polymerization and molecular weight distribution in the pulp, the profile of dope

rheology as function of cellulose concentration and molecular weight distribution,

the length-to-diameter (L/D) ratio in the spinneret orifices, and the degree of stretch