Page 453 - Handbook of Properties of Textile and Technical Fibres

P. 453

426 Handbook of Properties of Textile and Technical Fibres

O

O O O

O

O O

O

O

O

O O

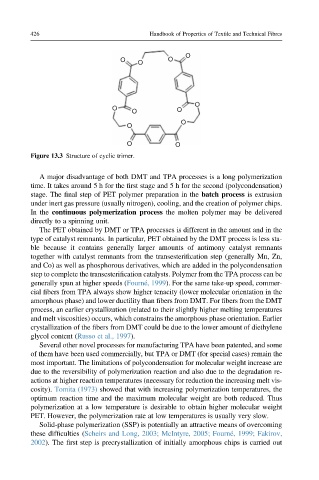

Figure 13.3 Structure of cyclic trimer.

A major disadvantage of both DMT and TPA processes is a long polymerization

time. It takes around 5 h for the first stage and 5 h for the second (polycondensation)

stage. The final step of PET polymer preparation in the batch process is extrusion

under inert gas pressure (usually nitrogen), cooling, and the creation of polymer chips.

In the continuous polymerization process the molten polymer may be delivered

directly to a spinning unit.

The PET obtained by DMT or TPA processes is different in the amount and in the

type of catalyst remnants. In particular, PET obtained by the DMT process is less sta-

ble because it contains generally larger amounts of antimony catalyst remnants

together with catalyst remnants from the transesterification step (generally Mn, Zn,

and Co) as well as phosphorous derivatives, which are added in the polycondensation

step to complete the transesterification catalysts. Polymer from the TPA process can be

generally spun at higher speeds (Fourné, 1999). For the same take-up speed, commer-

cial fibers from TPA always show higher tenacity (lower molecular orientation in the

amorphous phase) and lower ductility than fibers from DMT. For fibers from the DMT

process, an earlier crystallization (related to their slightly higher melting temperatures

and melt viscosities) occurs, which constrains the amorphous phase orientation. Earlier

crystallization of the fibers from DMT could be due to the lower amount of diethylene

glycol content (Russo et al., 1997).

Several other novel processes for manufacturing TPA have been patented, and some

of them have been used commercially, but TPA or DMT (for special cases) remain the

most important. The limitations of polycondensation for molecular weight increase are

due to the reversibility of polymerization reaction and also due to the degradation re-

actions at higher reaction temperatures (necessary for reduction the increasing melt vis-

cosity). Tomita (1973) showed that with increasing polymerization temperatures, the

optimum reaction time and the maximum molecular weight are both reduced. Thus

polymerization at a low temperature is desirable to obtain higher molecular weight

PET. However, the polymerization rate at low temperatures is usually very slow.

Solid-phase polymerization (SSP) is potentially an attractive means of overcoming

these difficulties (Scheirs and Long, 2003; McIntyre, 2005; Fourné, 1999; Fakirov,

2002). The first step is precrystallization of initially amorphous chips is carried out