Page 70 - Handbook of Properties of Textile and Technical Fibres

P. 70

Testing and characterization of fibers 51

Unrestrained,

Initial loop at relaxed fiber

room temperature

R o Heat R

treat a

(T,t)

Graphite

Graphite rod

block

R o R a

T,t

R = 4 or 8 mm

o

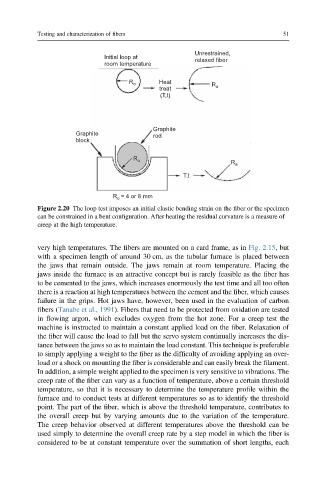

Figure 2.20 The loop test imposes an initial elastic bending strain on the fiber or the specimen

can be constrained in a bent configuration. After heating the residual curvature is a measure of

creep at the high temperature.

very high temperatures. The fibers are mounted on a card frame, as in Fig. 2.15, but

with a specimen length of around 30 cm, as the tubular furnace is placed between

the jaws that remain outside. The jaws remain at room temperature. Placing the

jaws inside the furnace is an attractive concept but is rarely feasible as the fiber has

to be cemented to the jaws, which increases enormously the test time and all too often

there is a reaction at high temperatures between the cement and the fiber, which causes

failure in the grips. Hot jaws have, however, been used in the evaluation of carbon

fibers (Tanabe et al., 1991). Fibers that need to be protected from oxidation are tested

in flowing argon, which excludes oxygen from the hot zone. For a creep test the

machine is instructed to maintain a constant applied load on the fiber. Relaxation of

the fiber will cause the load to fall but the servo system continually increases the dis-

tance between the jaws so as to maintain the load constant. This technique is preferable

to simply applying a weight to the fiber as the difficulty of avoiding applying an over-

load or a shock on mounting the fiber is considerable and can easily break the filament.

In addition, a simple weight applied to the specimen is very sensitive to vibrations. The

creep rate of the fiber can vary as a function of temperature, above a certain threshold

temperature, so that it is necessary to determine the temperature profile within the

furnace and to conduct tests at different temperatures so as to identify the threshold

point. The part of the fiber, which is above the threshold temperature, contributes to

the overall creep but by varying amounts due to the variation of the temperature.

The creep behavior observed at different temperatures above the threshold can be

used simply to determine the overall creep rate by a step model in which the fiber is

considered to be at constant temperature over the summation of short lengths, each