Page 244 - Handbook of Structural Steel Connection Design and Details

P. 244

Welded Joint Design and Production

Welded Joint Design and Production 229

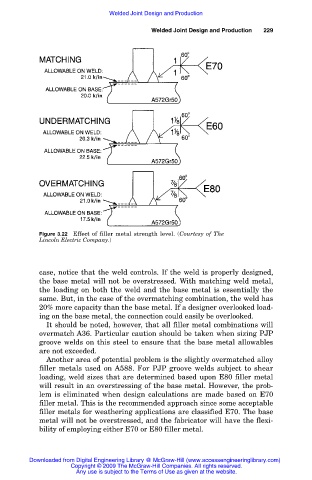

Figure 3.22 Effect of filler metal strength level. (Courtesy of The

Lincoln Electric Company.)

case, notice that the weld controls. If the weld is properly designed,

the base metal will not be overstressed. With matching weld metal,

the loading on both the weld and the base metal is essentially the

same. But, in the case of the overmatching combination, the weld has

20% more capacity than the base metal. If a designer overlooked load-

ing on the base metal, the connection could easily be overlooked.

It should be noted, however, that all filler metal combinations will

overmatch A36. Particular caution should be taken when sizing PJP

groove welds on this steel to ensure that the base metal allowables

are not exceeded.

Another area of potential problem is the slightly overmatched alloy

filler metals used on A588. For PJP groove welds subject to shear

loading, weld sizes that are determined based upon E80 filler metal

will result in an overstressing of the base metal. However, the prob-

lem is eliminated when design calculations are made based on E70

filler metal. This is the recommended approach since some acceptable

filler metals for weathering applications are classified E70. The base

metal will not be overstressed, and the fabricator will have the flexi-

bility of employing either E70 or E80 filler metal.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.